Reblochon Cheese Making Recipe Instructions

Making Reblochon

This cheese is for those who have developed a bit of experience with making semi soft cheese. There are a lot of details to follow in this guideline so I advise folks to read through before they make this cheese. The Reblochon is typical of many small cheeses made on the farm. The small disc of about 5-6 inches changes from a firm body to a totally transformed creamy paste during its 2-month aging. When ready, it appears covered with a dusty white surface mold overlayed with a slightly rosy colored surface created by the surface molds and bacteria. Our PLA gets its blending cues from the typical Reblochon of the Savoie region.

The key to success is getting just the right moisture as you drain the whey and transfer the curds to their mold and maintaining the proper wash regimen during aging with proper moisture. If the curds are too wet there is danger of a renewed late acid development, too dry and the final moisture will challenge a proper ripening. The final cheese will yield a mild flavor and aroma as well as a very elastic, almost flowing body. It is not as stinky as some of the other washed rind cheeses.

-

Heat & Acidify Milk

If using pasteurized milk add 1/2 tsp calcium chloride diluted in 1/4 cup non-chlorinated water to your milk and stir well.

Slowly heat the milk to 94°F. Once the milk is at temperature the cultures can be added. 94°F is at the high end for the mesophilic and low end of thermophilic culture ripening.

Once the cultures are mixed in, the milk now needs to be kept at this target temperature for ripening.

Hold the milk quiet for the next 1.5 hours to allow the culture to begin doing its work. As the cultures convert lactose to lactic acid they will increase the acidity and help the rennet form a firmer curd when it is added.

During this wait time, the molds and drain cloth should be sanitized and laid out onto a draining surface.

Culture Info:

- Flora Danica, MM100, or AromaB are mesophilic bacteria blends working at the top end of their comfort zone. This combo provides for early acid development and some open texture and aroma.

- MY800 is a special blend of a slower working thermophilic bacteria. The slower and more controlled acid development will show in the final cheese transformation and texture. The MY800 is ideally adapted to the lower thermophilic ripening temperature.

- PLA is a late ripening mold for the cheese surface and is a pre-blended mix of Yeasts, B.Linen, and Geotrichum. The yeast and Geo will begin the ripening by growing and reducing the initial acidity. As they work, the texture of the curd changes to a more translucent and creamy texture. The bacteria surface is not going to be the bright red/orange of other b.linens. The final rind will be a light rosy color with an overgrowth of white powdery mold/yeast.

Note: MY800 and PLA closely match what has been found in the regional cheese of the Savoie.

-

Coagulate with Rennet

Diluted the rennet in 1/2 cup non-chlorinated water and add to the milk. The milk now needs to sit quiet for 35 minutes while the culture works, and the rennet forms a firm curd.

You should notice the milk will begin to thicken at about 12-15 minutes but allow it to coagulate to firmness at about 35 minutes. It is always best to check for a firm coagulation, if it seems soft allow it to go as much as 50% more time. The next time you make the cheese, adjust the rennet amount if needed (more rennet for a quicker set). The thermal mass of the milk should keep it warm during this period. It is OK if the temp drops a few degrees during this time, you can heat it back to temp after cutting.

-

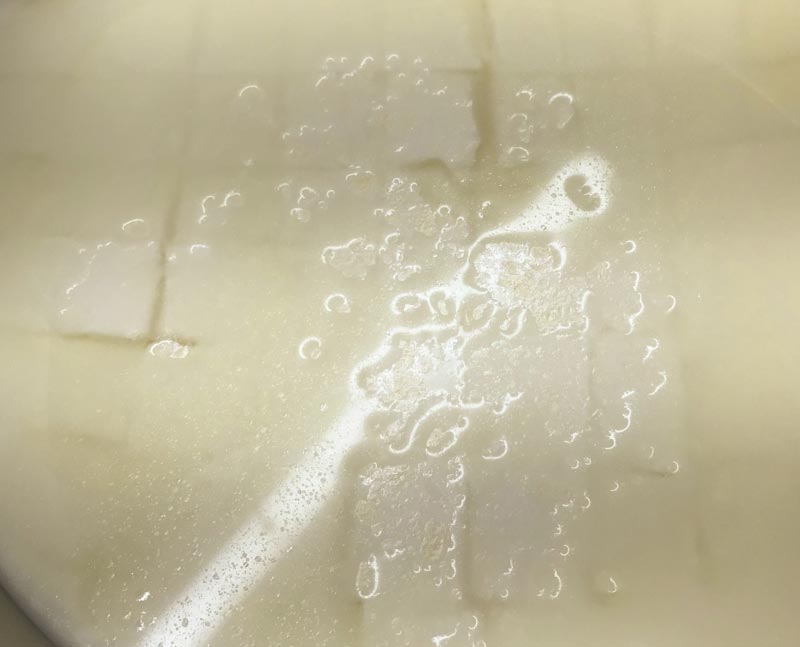

Cut Curd

Once you have determined that the milk has set well, begin with vertical cuts about 1-1.5 inches apart cutting in both directions. Then allow this to rest about 5 minutes. This will allow the initial cut surfaces to firm slightly for five minutes before continuing.

Now cut the curd mass as evenly as possible to about 1/4” pieces. Allow the cut curd to rest for another 5 minutes so that the cut curd surfaces can heal again. I use a big whisk with thin wires for this, but a knife, ladle or other implement can work.

-

Stir Curds

Stir slowly for 10-15 minutes while maintaining the 94°F temperature. The speed of stirring should be just enough to keep the curds buoyant and moving. The curd is ready once it begins to show a defined structure and just as it mats in the hand. This is a rather subjective descriptor but the final texture and weight in the hand comes with experience.

I was taught in France to take a thin layer of curds in the upturned flat of the hand, allow them to drain and slowly turn the hand down. When the curds seem to stay and not fall back into the vat, the curd is dry enough to mold. This may take a few trials to get right.

When ready, allow the curds to settle for 5 minutes then remove the whey down to about 1” above the curds.

-

Transfer Curd to Molds

The forms should be sanitized and lined with cloth already. A little of the warm whey should first be poured into them to warm the forms a bit. You can then scoop or pour the curds into the warmed forms. I normally use a stainless-steel shallow bowl to transfer.

The transfer is a heavy mix of curds plus whey. Including the whey mix helps form a good tight cheese body.

Do the transfer quickly and continue to fill the forms as fast as they drain. Top the curd up until all the curd has been used. If there is too much curd, this may have been due to transferring curds before enough whey had drained. The mounded curds should recede quickly into the form as the draining continues. Normally the tops are mounded with a bit of hand pressing initially.

The curds will be suspended in the whey as you transfer them. The functionality of this step is to remove as much air from the curds as possible during molding, which will result in a tight, compact curd mass and few mechanical openings. This will facilitate the small gas holes that the cultures produce during the early aging process.

-

Pressing & Turning

Following the below schedule for turning should ensure a well consolidated and drained cheese that will be ready for salting and aging:

- The moist curds, along with the help of the whey, will consolidate quickly and should be ready to turn in about 5-10 minutes. Once turned in the cloth, the follower is placed on top and a very light weight of 3lb is applied to each form.

- The cheese should be turned again in 30 minutes with same weight.

- Turn again in 60 minutes with same weight.

- Turn again in 90 minutes with same weight.

During the above schedule, the forms need to be kept warm. I drain in a large insulated sink and use large pans of warm water to keep warm. After the final turn the cheese can be placed back in the form without the cloth. After about 4 hours from transferring the curd from vat, a test with our pH strips should indicate about 5.6-5.7pH.

The forms with cheese should be now moved to a 60-62F space with high moisture of 95%. A cooler with warm jars of water work well for this. Here I use my insulated sink with insulated cover for this. By the next morning (12-24 hours) the cheese should show 5.3-5.4pH. The final cool temperature will begin to allow the yeast to work at populating the surface.

Note: If you don’t have a means to test the pH, here is my guideline. This is the same guideline I teach in my workshops:

- pH 6.2-6.5 the curds and whey should taste sweet like milk

- 5.8-5.7 the curds will still have a slight sweetness but nearing neutral

- 5.5-5.4 they will taste neutral, neither sweet nor acid.

- 5.2-5.3 a slight acid tang develops

- 5.1-4.9 a definite acid tang

- 4.7-4.4 and below the taste begins to have the tang of a euro style yogurt

-

Salting

You can either choose to brine or dry salt these. Most of the people I visit in France brine their Reblochon.

Brining: You should have a saturated brine prepared for salting this cheese.

You will find all of the details you need on brining here If you need to prepare it fresh.

I keep my brine at cave temp of 52F and move cheeses to my cave at this temperature an hour or two before brining. Brine time will be about 90 min, flipping at the halfway mark and sprinkling salt on the top of the cheese. Dry the cheese down after brining.

Dry Salting: Dry salting is simply a matter of using about 2% of cheese weight in medium grain cheese salt and applying half of this on one side then waiting for it to dissolve and sink into the cheese body then doing the same for the other side. Approximately 3 tbsp of salt for this 4 gallon batch.

-

Aging

Prepare Wash: About one day before the cheese is done in the warm aging step below, prepare a 6% brine wash with 1 cup of water, 1 Tbs salt, and a pinch of PLA Allow this to sit at 62F for a day, then store it in the fridge.

Warm Aging: After salting the cheese goes back to the 62F/95% space for 4-6 days, so the surface molds can develop (provided by the PLA culture). First yeast develops, followed by geotrichum followed by a tan to rosy color from b.linens. During this warm room ripening the cheese will begin to spread out slightly from a 5 1/8 inch diameter to 6 - 6 1/2 inch.

The yeast and geotrichum will grow in as a greasy/slippery coating on the surface with a very fruity, yeast-like aroma. Once these are noticed, the cheeses are ready for the cooler aging space

Washing and Cooler Aging: Pour a few tablespoons of the prepared wash into a bowl. Dip a sanitized cloth into the wash until damp and wash the top surface and sides to to remove some of the greasy surface, allow the surface to dry slightly. Turn cheese and repeat on the bottom surface then allow the newly washed surface to dry.

After washing place the cheese in a covered plastic box with an aging board (pine) cut to size on the bottom. Move the covered box into a cool cave (52F/95+%) to contine aging.

Repeat this same washing every 2-3 days until you see a white film of mold developing. The surface will become dampish after washing so be sure to let the surface dry before placing it back in the cave.

Within 14-15 days from beginning the wash, you should notice some light white mold growing and a slight rosy color on the surface developing, this will be very light. At this time there should also be a softening of the cheese and very distinctive aromatics these are signs that the cheese is ready for the next step in aging, maturation.

If done properly no blue, dark, or fuzzy mold should grow. That is one of the beauties of washed rinds that monks discovered.

Note: Never wash your boards with detergent; just hot water scrub and dry in the sun. This will allow them to harbor a complex blend of washed rind bios over time.

-

Maturation

At this point the surface has been well established and the curd transformation should be well under way and now it is time to slow the ripening down a bit down a bit by moving to a cooler space.

The Reblochon can now be wrapped in a paper designed for washed rind cheeses and moved to a cooler space. Before wrapping dry the cheese down to prevent moisture sticking the wrap to the mold surface. The wrap will control moisture loss but still allow fresh air in and any byproducts to escape. They are designed to stabilize the cheese. I move mine to a 42F/is controlled space here (thanks to my brewing and lager space).

In France Joseph Paccard in Manigod does his maturation at 38F.

Cooler temperatures will allow a longer maturation and more complex cheese but he also moves his back up. To a warmer room before packing for sales. This cooler temperature will slow the aging down and allow for a nice even transition from surface to center of curd transformation.

The cheese should be held here for another month and a half. Just remember to turn it and check on it every day or two

-

Finished Reblochon

The normal aging time for a Reblochon in France is 54-58 days from salting to market.

How long should the wash go for and cheese age? This depends on the character you want.

Too much surface aroma competes with the sweet flavor of the cheese.

When the cheese is ripe the curd transformation should have changed from the rather stiff and rigid curd mass to a somewhat translucent paste, needing only a warm room to flow from its rind.

Te aroma should remind you of warm milk and hay in the fields as well as a good mustiness from the cellar The flavor is mild yet distinctive. Somewhat meaty but rich and cream-like.

This one is one I purchased from my favorite farm but after a few days of travel lunches.

I have been to several regional competitions for Reblochon in the Savoie area and I can say that if there are 40 Reblochons on the table by different producers, there will be 40 different Reblochons.

This is because each makers family has made them for generations and how they were instructed to make their cheese.

I always find it interesting to hear what the judges have to say about the cheese on the table and why one is better than the other.