It is easy and fun to make cheese at home. When starting out, there are three basic components to think about, ingredients, equipment and the process.

In this article you will learn about the equipment used to make cheese at home. You may already have some items in your kitchen, including a colander and measuring spoons. Adding a few more items to your supplies, including a dairy thermometer, curd knife and butter muslin, will make the cheese making process even easier.

Cleaning and Caring for Equipment

Cleanliness is a top priority in cheese making. All equipment needs to be clean and sterilized before use, and should be cleaned directly after use as well. Keeping everything as clean as possible will help cut down on the chance of rogue bacteria in your cheese. The process of cheese making is largely influenced by the growth of friendly bacteria and we want to create the ideal environment for them to thrive. With this in mind, we must remember, this environment is also a wonderful place for rouge bacteria to thrive too. Being as clean as possible helps the friendly bacteria grow without having to compete against other bacteria.

A great way to sterilize equipment before you begin is to fill your cheese pot with water and add your submersible, heat safe equipment. Then bring the pot of water to a boil and maintain for 15 minutes.

We suggest washing and sterilizing all equipment once done with cheese making as well.

Another option is to use a sanitizing solution recommended for dairy equipment.

Cheese Pot

A pot is one of the most used pieces of equipment in cheese making. Before running to the store you may want to check your kitchen cupboard, chances are you already have a pot that will work well for cheese making. Following are some guidelines of what to look for in a good pot.

Type of Material

Be sure the pot you select is made of a non-reactive material; stainless-steel, heat safe glass and un-chipped enamel are all great options. Steer clear of any aluminum, or any other reactive metal, Teflon, and chipped enamel; these materials can have an adverse chemical reaction when used in cheese making.

Stainless-steel is our favorite option since it is easily sterilized and you won’t have to worry about cracks or chips. If your pot has a thick bottom and wall it will help cut down on scorching and also maintain a more consistent temperature throughout the cheese making process.

What Size

The size of your pot will depend on your recipe and how much milk you want to use. Some recipes call for only a quart of milk, others will need at least 2 gallons, or perhaps you are looking to use 5 or more gallons to make a large batch or multiple cheeses at once. Keep this in mind when looking for a pot and size it accordingly. Remember that you will be adding about one cup worth of ingredients to your milk and you will also want plenty of room for cutting and stirring your curds.

Additional Things to Look for in a Good Pot

- If you have a choice, get a pot that does not have rivets on the inside since they can be harder to sanitize.

- When working with high temperatures a double boiler is the best way to prevent scorching.

- A pot with a lid can be helpful in the cheese making process to maintain heat when letting your milk set

Thermometers

A good quality dairy thermometer is an important item to have on hand when making cheese. Maintaining the correct temperature will help give you the most consistent results and being able to rely on your thermometer will make the process much easier. Most dairy thermometers even come with a clip that will attach to the side of your pot, this is a helpful feature since you won’t even have to hold it while checking the temperature.

There are many varieties to choose from including glass, digital or a dial head. No matter your choice be sure it is easy for you to read the temperature gauge for a quick reference while making cheese.

Calibrating

All good quality dairy thermometers will come pre-calibrated to give you an accurate temperature right off the bat. Some thermometers also allow you to re-calibrate if the readings are slightly off. To check for accuracy bring a pot of water to a boil, the temperature should read 212F. If your thermometer is reading a different temperature it may be time to re-calibrate. For a dial head thermometer there is usually a nut on the underside that you can turn gently until it reads the correct temperature.

Please Remember Candy is Not Cheese

Often times we are asked if a candy thermometer will work for cheese making. Unfortunately candy thermometers are usually calibrated at a higher temperature; because of this they can give an incorrect reading when used for making cheese since you will also need accuracy at lower temperatures.

Measuring Cup & Spoons

Measuring Cup

The best material for a measuring cup is glass, since it is non corrosive and you will be able to easily see what you are measuring. Other materials that will work are stainless steel and plastic. If using plastic be sure there are no scratches since they can make it difficult to sanitize.

Measuring Spoons

Stainless steel measuring spoons are best for cheese making, a household pair should work just fine. Occasionally there will be particularly small measurements such as 1/16 tsp, 1/32 tsp or even 1/64 tsp, it can be helpful to have a set of spoons that include these measurements so you are able to add ingredients more precisely.

Stainless Steel Skimmer

A stainless steel skimmer or slotted spoon is a great tool and will be helpful with many steps in the cheese making process. You can use it to add and properly mix rennet into your milk, mix in cultures and some additives, stir curds, and transfer curds into molds or a lined colander. A stainless steel ladle is preferable although a plastic one will work too. If using a plastic ladle take extra care when sanitizing and cleaning to help eliminate any bacteria that may try to hide in all those tiny holes.

Curd Knife

A curd knife should have a thin stainless steel blade long enough to reach to the bottom of your pot and usually has a rounded tip so as not to scratch the pot. You may have a knife that will work to start with but typically for large batches of cheese an actual curd knife does best.

Colander

Colanders are used quite often in cheese making, chances are you already have one on hand. Stainless steel, enamel and plastic are all fine to use, but steer clear of aluminum or any other reactive metal. You will use the colander in conjunction with butter muslin or cheese cloth. The cloth is used to line your colander when curds are placed inside to drain and expel whey.

What Size

Soft cheese does not expel much whey until it is in the colander, so if your recipe calls for one gallon of milk your colander will need to be able to hold the equivalent amount of curds.

When making hard cheese, a good portion of whey will have already separated from your curds, the colander should be able to hold at least half the amount of milk you started with.

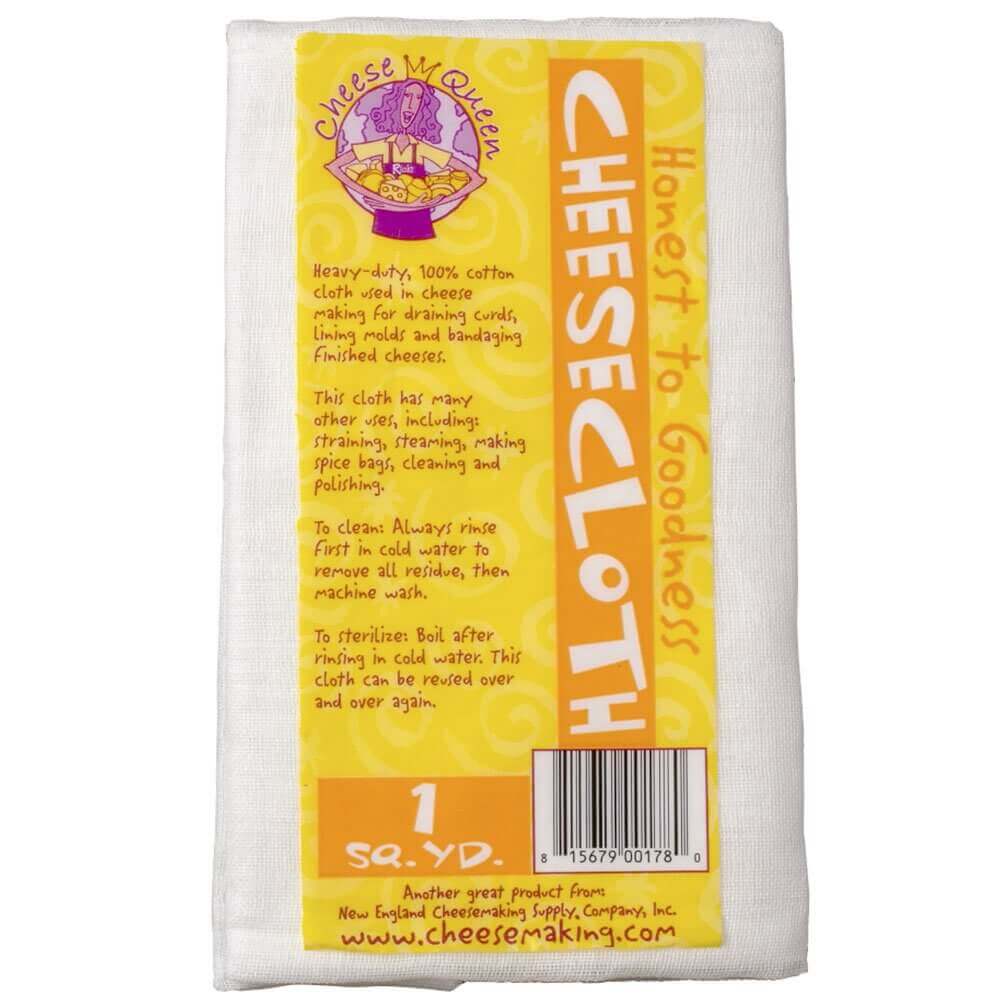

Cheese Cloth & Butter Muslin

Cheesecloth is a woven cotton gauze-like material which is used for lining molds when pressing cheese. Butter muslin has a tighter weave than cheesecloth and is used for draining soft cheese; it can also be used for lining molds as well. These types of cloth are a staple in cheese making and a few should be kept on hand. If taken care of properly your cloth will be able to be used time and time again.

How to Clean it

As soon as you are done with your cloth, rinse it thoroughly in cold water, then wash in warm water. If you use soap be sure it is unscented and rinsed out thoroughly. Hang your cloth to dry and store in a zip lock bag until you need it again. Occasionally boiling your cloth with some baking soda will help keep it fresh. Each time you use your cloth, sterilize it in a pot of boiling water to be sure it is ready for cheese making.

Tip: If there are cheese curds stuck to your cloth rinsing it in whey before cleaning may help to remove them.

Beware of "Cheesecloth" in the Grocery Store

Although you may be able to find cheesecloth in a local grocery store be cautious of a loose weave. If you try to put curds into a loosely woven material they may end up going right down the drain.

Cheese Molds

Molds are forms used to shape your cheese. They typically have holes or perforations to allow whey to drain properly. Some have open bottoms while others have perforated bottoms. Common materials are stainless steel or food grade plastic since they are both easy to clean and sanitize. Traditionally molds were made out of reeds, wood or clay. On occasion you can still find these old style molds. Although extra caution is needed since these materials are not as easily sanitized, they can be great fun to work with.

Note: If using a homemade mold be sure it is not made out of a plastic or metal that can leach into your cheese. PVC molds are not considered food grade and can leach toxins into your cheese.

Do You Need a Follower

Followers are discs that are placed on top of your curds and allow weight to be evenly distributed when pressing your cheese. If your cheese needs to be pressed you should use a follower to give it a uniform shape on both the top and bottom. When making soft cheese you will not need to use a follower since the curds will consolidate under their own weight.

Many Different Shapes and Sizes

Molds come in all different shapes and sizes, some cheese will call for a specific type of mold such as Camembert, Ricotta Salata, Basket Cheese… When selecting a mold it is good to know what size batch you are making and whether it is a soft or hard cheese. Our recipes will help guide you in selecting the correct mold and many times will even give you multiple options to choose from.

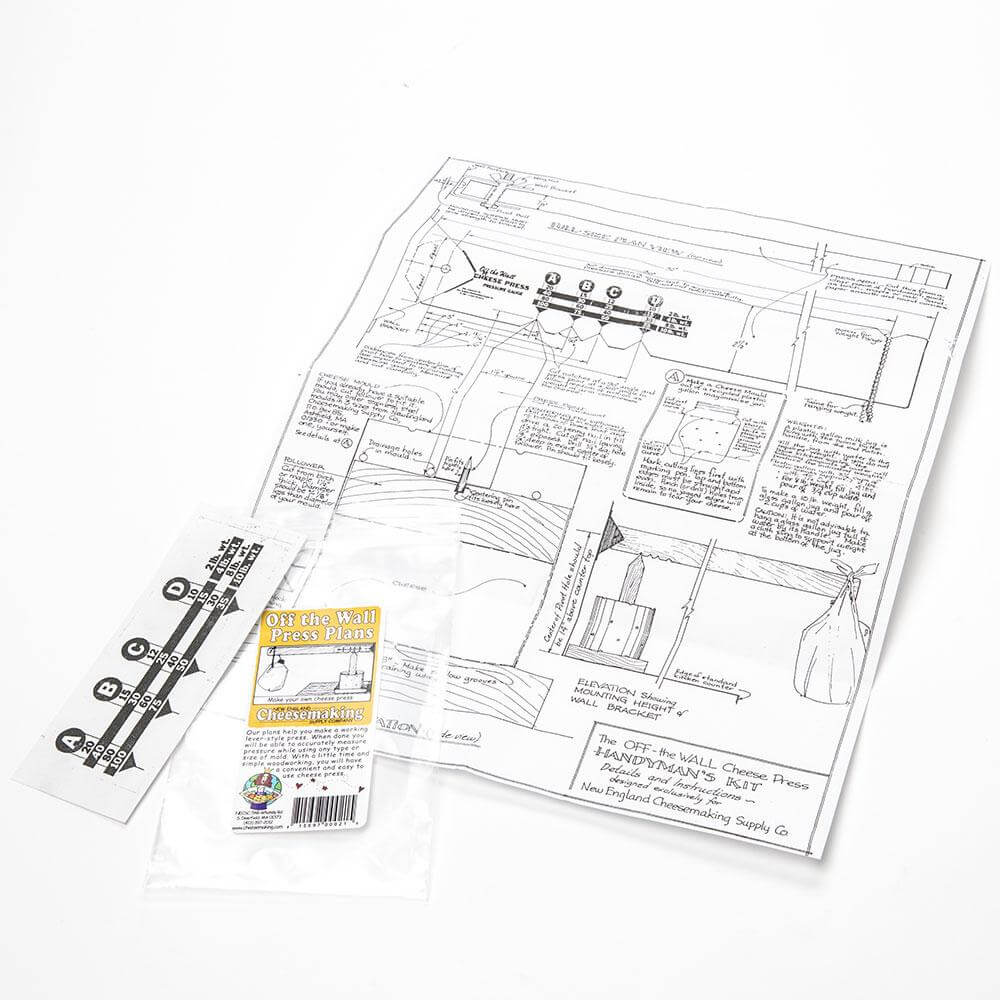

Cheese Press & Drip Tray

Cheese Press

When making hard cheese you will need to consolidate your curds by applying weight once they are in a mold. The easiest and most consistent option is to use a cheese press. When selecting a press be sure it is both easy to assemble and clean. A good press will also have a gauge to tell you how much weight is being applied to your cheese.

Note: If you do not have access to a cheese press you can use weights found around the house to add pressure to the curds. We have seen customers us jugs of water, bricks, heavy books or hand weights, you can use a scale to check on the weight of a particular item.

Drip Tray

A drip tray is typically made out of stainless steel and is used under a mold when pressing cheese to help direct the whey into a pan or the kitchen sink.

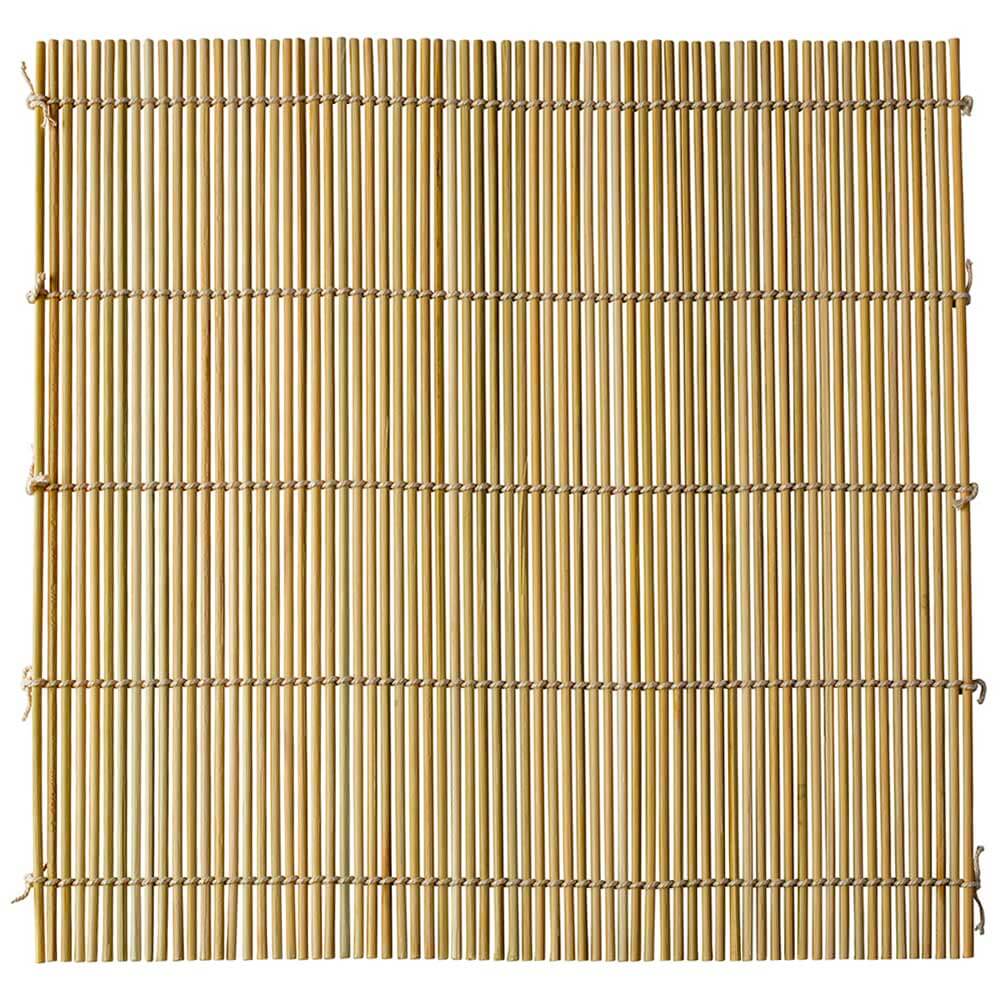

Cheese Draining Mats

Draining mats are typically made of food grade plastic or reeds. A mat will help the air to circulate on the underside of your cheese while drying as well as aging. If a mat is not used moisture can build up and interfere during the drying and aging process.

Waxing Brush & Pot

Waxing Brush

One of the easiest ways to apply wax to your cheese is with a brush. When selecting a brush look for one with natural bristles since synthetic ones can melt right into your wax. Also plan on designating your brush solely to waxing cheese since it is nearly impossible to remove all the wax after use. Between uses you can keep your brush in a zip lock bag or store it in with your wax.

Waxing Pot

You will need to melt wax before applying it to your cheese. A great way to do this is in a pot on the stove. Another good option is to use a heat safe glass or metal container submersed half way in a pot of water; this will allow the wax to heat indirectly. Working with wax can be a bit messy; one way to make clean up easier is to dedicate your pot or container solely to cheese wax. Once done, you can let the wax solidify and cool within your pot or container then cover it and store until you need to use it next. Using aluminum foil to line surfaces while waxing cheese will catch drips and help with clean up too.

Cheese Wax

Wax is applied to a hard cheese after pressing and drying for the aging process and is one of the most convenient ways to protect cheese during aging. Waxing cheese can help in easily maintaining the desired moisture level within your cheese.

Cheese Wax

We carry four different colors of cheese wax, red, yellow, clear and black. Choosing a color is based mostly on personal preference although red is by far our most popular. If you are new to cheese making you may want to go with yellow wax since it will allow you to see what is going on under the surface without having to take the wax off. Our cheese wax is a combination of paraffin and microcrystalline which is ideal for cheese making. This combination is pliable so it tends not to crack during the aging process and is easily removed from your cheese after aging.

Beeswax

Along with our cheese wax we also carry an all-natural beeswax, if you choose to use beeswax please note that it is much more brittle and can crack when aging cheese. We suggest adding vegetable shortening to beeswax to help make it more pliable.

Reusing Wax

When your cheese is done aging, and you have taken off the wax there is no need to throw the wax away. It can be reused over again many times. To prepare your used wax for reapplication simply melt it down and strain it through cheese cloth. This will eliminate any particles from your wax. The high temperatures it takes to melt wax will sterilize it too.

Equipment for Waxing

There is no way around it, waxing is a messy business. We suggest using older equipment for waxing and dedicating it solely to waxing thereafter. Ideally you will use the same container to heat, melt, cool, solidify, and store your wax in. This can a heat safe glass container, a coffee can, an older pot with a lid. Using the same container for all of these steps will cut down drastically on clean up, along with preparation for the next time.

If you’re applying wax with a brush be sure it has natural bristles otherwise they can melt. To cut down on cleaning time even more you can keep your brush in the same container as your wax and let the wax melt off when you heat things up next time.

Caution on Heating Wax

It may seem to take a long time for wax to go from solid to liquid, but once it has liquefied, the temperature will rise quickly. Make it a habit to constantly monitor the temperature of your wax. If wax reaches flash point, vapors produced are extremely flammable. The flash point of wax is typically above 300° F. Please do not let your wax exceed 250F.

Never leave the wax unattended on the stove.

Cheese Wrap

There are many different types of cheese wrap. Some wraps can be used when aging cheese while others are used for storing a finished cheese.

Clear Breathable Wrap

This wrap is comprised of a single layer of clear cellophane. It is breathable and will allow the proper exchange of moisture and gas for fresh air which helps the ripening cheese surface. It is available in both a mold ripened and a washed rind version.

Two Ply Cheese Wrap

This wrap comes in two varieties, one for soft and mold ripened cheese the other for washed rind cheese.

The wrap for soft and mold ripened cheese is comprised of a paraffin coated inner layer which lies against the cheese surface and a micro-perforated outer layer. The inner layer helps pull moisture away from the cheese surface and the outer layer will allow gas to exchange while controlling moisture loss.

The wrap for washed rind cheese is comprised of a sulphurized grease proof inner layer with a micro-perforated polypropylene outer layer. The inner layer will help pull moisture away from the cheese, restrain surface mold growth and will prevent crystal formation which can result in a grainy or sandy rind. The outer layer will allow gas to exchange while controlling moisture loss.

Foil Wrap

This warp is a great option for a finished cheese. It makes a nice presentation and will help slow moisture loss. It is best used on a well-aged cheese.

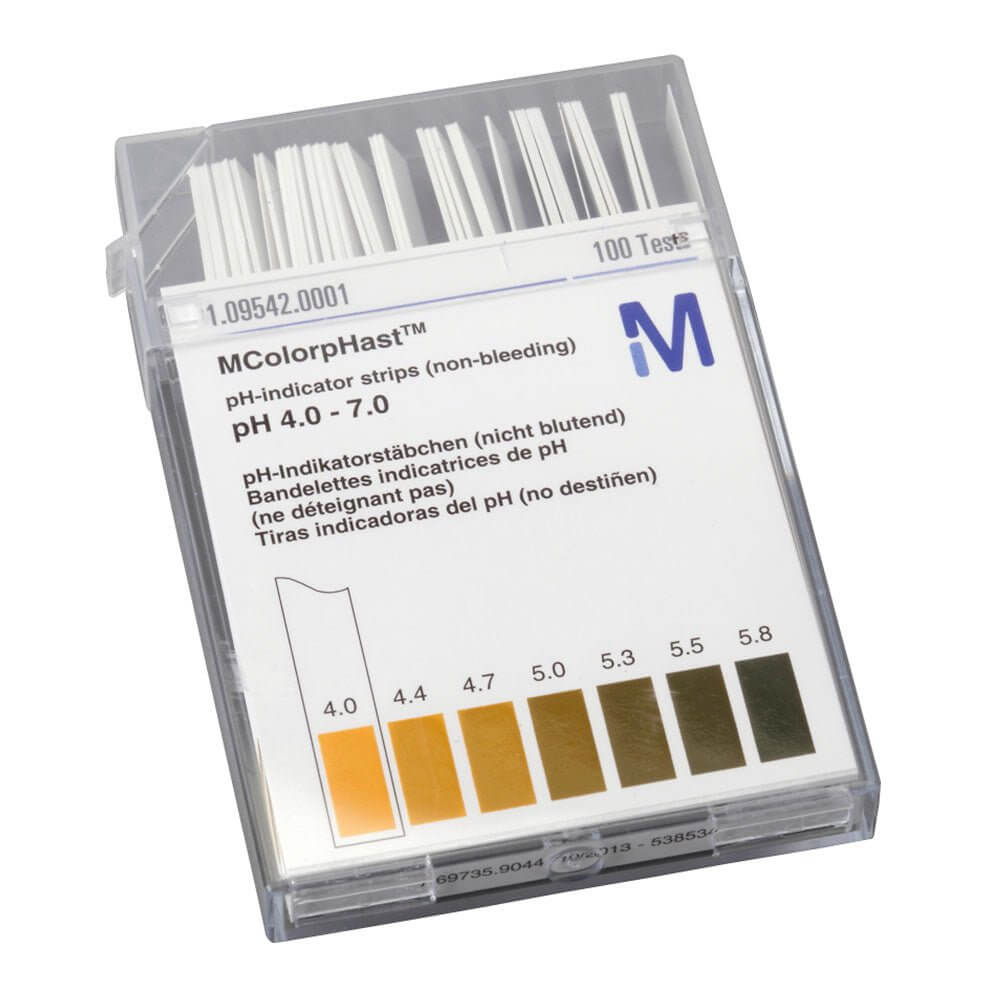

pH & Acid Testing Equipment

This equipment is used to measure the pH and acidity level of your milk, curds and whey. Monitoring the pH and acidity is not necessary when first starting out in cheese making but once you are comfortable with the cheese making process and you want to improve results and consistency from batch to batch monitoring the pH and acidity can help.

During cheese making the acid and pH levels are constantly changing and can help let you know if your cheese is on track for the recipe you are working with. Having levels that are too high or too low can affect both the consistency, and taste of your finished cheese.

Yogurt Maker

A yogurt maker will help give you the most consistent results. When making yogurt milk will need to ripen for at least 5 hours at a warm temperature, a yogurt maker will help with this. There are many different yogurt makers including electric versions and non-electric ones. They typically do not take up much space on the counter and if you are making yogurt regularly it can be helpful to have one on hand.

Notebook

Taking notes will help you to remember some of the wonderful “mistakes” you make along the whey. Sometimes that “mistake” you made ends up producing a spectacular cheese and by golly you’ll want to make the same “mistake” again. We highly recommend keeping notes while making cheese, they will be invaluable to look back on from batch to batch and if using farm fresh milk from season to season as well. A cheese makers notebook is a treasured item; we have quite a few tattered books lining our shelves these days and can’t seem to part with a single one.

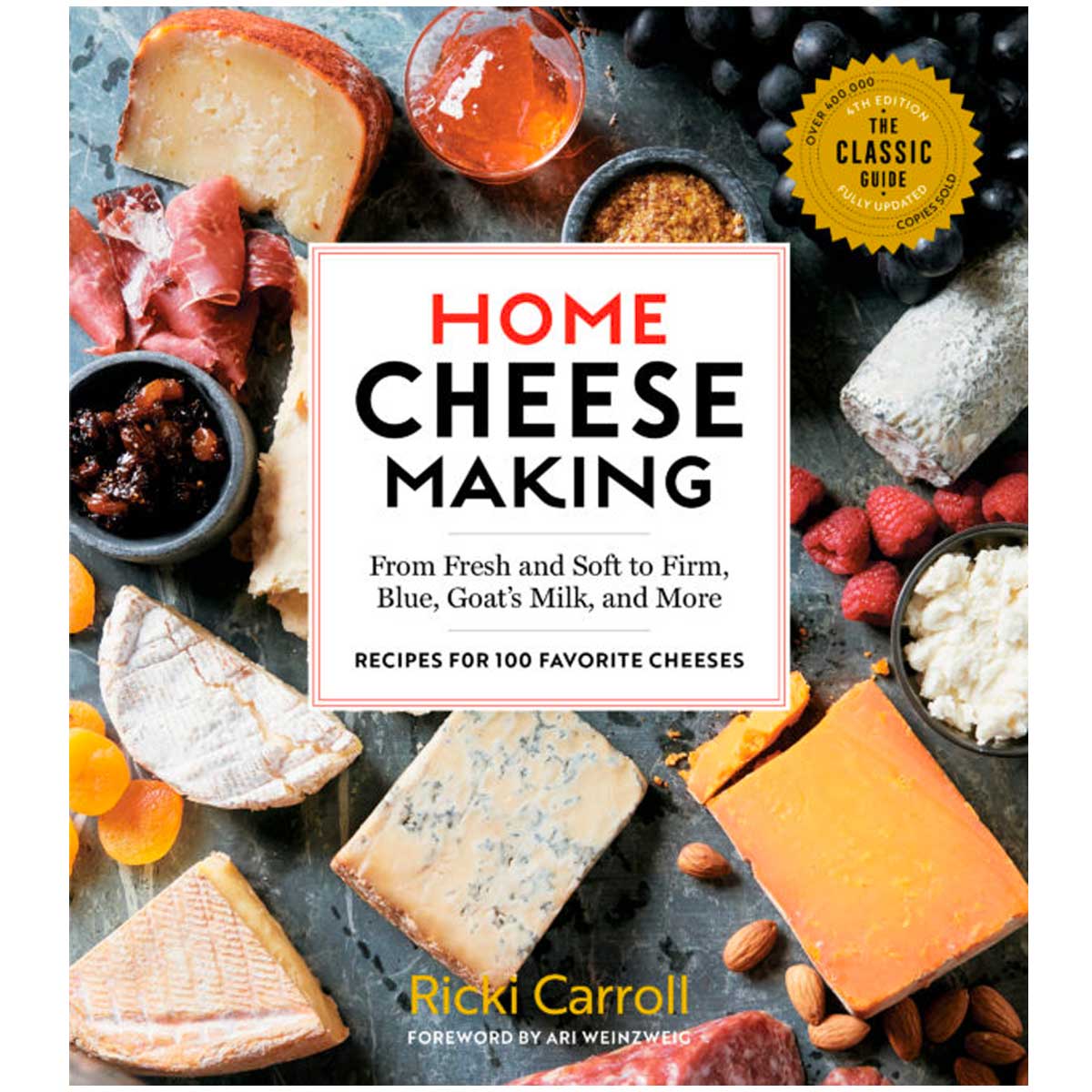

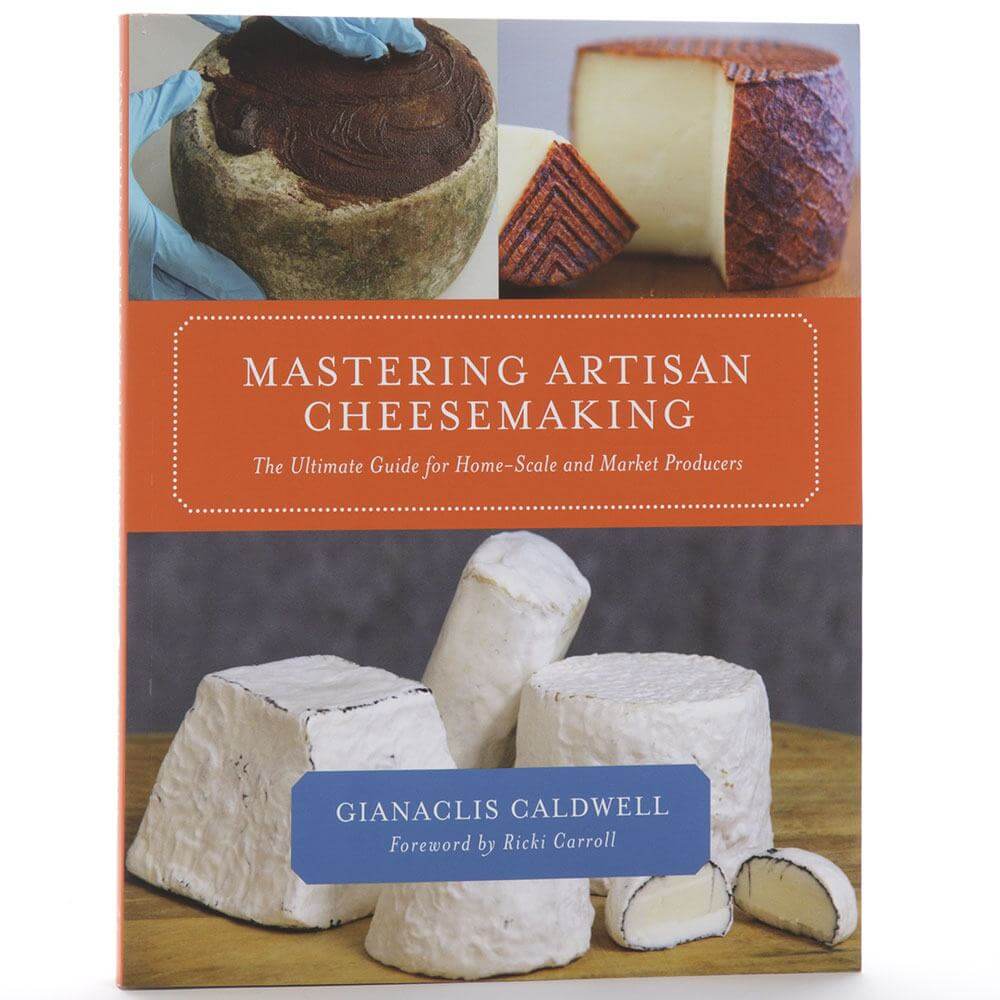

Learn More About Cheese Making

MOST POPULAR CONTENT

Cheese Makers Also Read

Cheese Making Recipes

Make Your Favorite Cheese

Learn how to make 30 Minute Mozzarella, in your own kitchen. With just a...

Make 30 Minute Mozzarella right at home with a simple water batch method...

This wonderful recipe goes above and beyond traditional Alpine style che...

This recipes focus is on making an Alpine style cheese, but not followin...