Vacherin d'Abondance Cheese Making Recipe

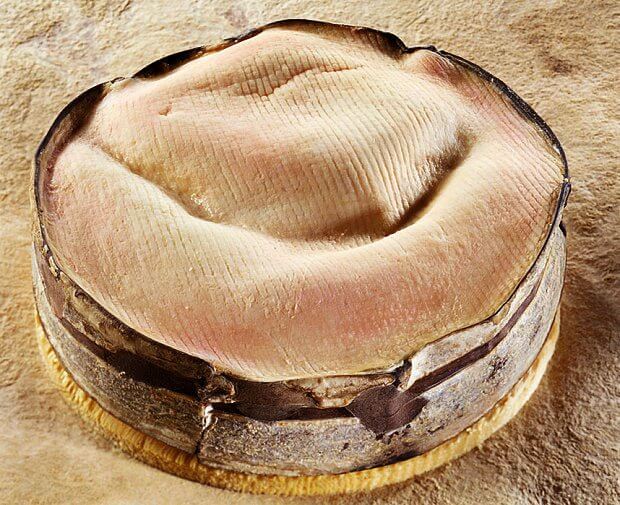

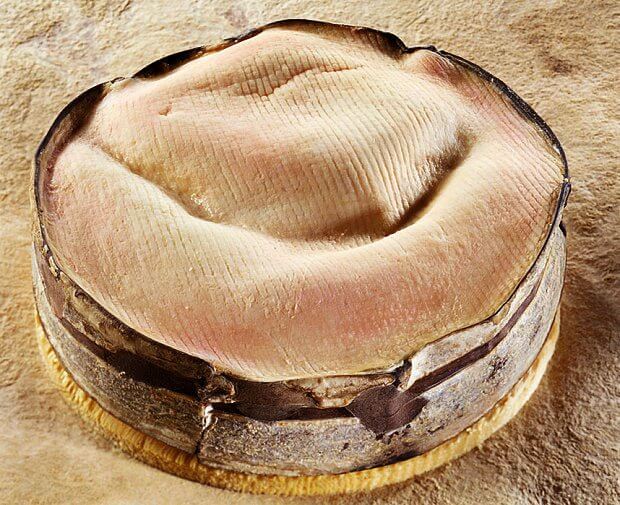

Vacherin d'Abondance is traditionally made in the valley of Abondance, France. It is produced in small quantities after the cows come down off the high summer pastures and into the barns in the valley during the cold months.

It's history can be traced back to the 1400s. Today the only real Vacherin d'Abondance is made from a single producer in the valley. In 2005 production had ceased, until 2015 when a young man took it upon himself to bring this wonderful cheese back to life.

This special cheese is traditionally ready in the winter season and ripens to almost a spoonable consistency. It is contained only by a strip of bark from the local alpine forest.

-

Yield

2 Pounds

-

Aging Time

~1 Month

-

Skill Level

Advanced

-

Author

Jim Wallace

Vacherin d'Abondance Cheese Making Recipe Info

About Vacherin d’Abondance

Disappearance and Revival

Making Vacherin d’Abondance

Flavor, Form, and Legacy

Ingredients

Total price for selected items: Total price:

Instructions

A Recipe for Making Vacherin d'Abondance Cheese

Making of the curd and draining does not present much of a challenge other than getting the absolutely best and freshest milk you can find. However, The more difficult part is the aging of this cheese. It requires daily attention and turning to get to the finish line. Too moist and it will show a different surface development that can go very wrong but too dry and the enzymes have a hard time doing what they need to do. Final ripeness depends on an even transformation of the cheese.

-

Acidify & Heat Milk

Begin by heating the milk to 86-90F (higher temp for higher fat milk). You do this by placing the milk in a pot or sink of very warm water. If you do this in a pot on the stove make sure you heat the milk slowly and stir it well as it heats

Place the spruce strips into warm water to allow them to rehydrate during the next few hours until needed. This will make them very supple and easy to wrap around the cheese.

Once the milk is at temperature the cultures can be added. Both MA4002 and Geo are added at this time.

The MA4002 is the culture that best represents the basic culture mix traditionally found in raw milk (although not quite as complex a community). It consists of both a Mesophilic component similar to MA011 or C101 and a Thermophilic component similar to TA061 or C201. The amount of culture added for this cheese is quite low for a long slow acidification which has always been typical for this cheese.

To prevent the powder from caking and sinking in clumps sprinkle the powder over the surface of the milk and then allow about 2 minutes for the powder to re-hydrate before stirring it in well.

The milk now needs to be kept at this target temperature until it is time to ladle the curds. Hold the milk with culture quiet for the next 90 minutes to allow the culture to begin doing its work. It will be very slow initially but will soon kick into its more rapid rate of converting lactose to lactic acid.

While you are waiting, use the time to sanitize the bowls and cloth for draining.

-

Coagulate with Rennet

Add about 1ml of single strength liquid rennet. Yes, this is a very small amount of rennet for this amount of milk and will emphasize the mixed lactic/enzymatic character of the final cheese.

The milk now needs to sit quiet for 45-60 minutes while the culture works and the rennet coagulates the curd . The thermal mass of this milk should keep it warm during this period. It is OK if the temp drops a few degrees during this time. You should notice the milk beginning to thicken (flocculation) at about 20-25 minutes. Allow the coagulation to continue until you can test a firm curd for ladling (look for a proper break)

-

Thansfer the Curds

Once you can test for a firm curd spread your draining cloths over each bowl and begin to transfer the curds. Slice a thin section from the curd mass and place into each cloth in a round robin fashion until all of the curds have been removed from the pot.

-

Tie Corners of Cloth

After transfering the curds, the four corners of the cloth should be knotted to tighten the curd. Leave the curd mass in the whey that collects for about 1/2 hour and then untie the cloth and retighten into a more consolidated package. Drain off excess whey each time. The curd should begin cooling down to about 65-75F room temperature.

-

Wrap with Spruce

After about 2 hours the spruce strips are used to encircle the draining curd and its cloth and restrain its form as it drains (traditionally they would notch the spruce but using an elastic band works best these days).

The total draining time should take about 8 hours and the cloth and spruce strip should be retightened and whey drained about every hour. During all of this time the cultures are still working and the cheese continues to develop its lactic character.

-

Move to Cheese Cave

Once the curds have drained well the cloth can be carefully removed, the spruce retightened and ready to be carefully moved to the cave (they will be very tender at this point)

The aging space should be about 52F and of good moisture 85-90% (used covered plastic boxes if you have trouble with this).

The cheese is still undergoing its lactic activity and moisture will continue to weep from the cheese while the cheese cools. Placing some drain cloth under the cheese, now and when it's aging, will absorb this moisture and act to buffer the needed moisture for the cheeses (will wick the moisture away from the cheese but keep the surrounding air higher in moisture).

-

Salting & Aging

The next morning the cheese can be salted at about 2% of salt to cheese weight. Apply this salt over 2 days. Salt one side at a time.

Following this the cheese needs to be attended to daily. Turning it on a daily basis is essential.

The first thing you will notice is that the surface becomes greasy or slimy, caused by natural yeast in the surroundings. This sets the stage for the Geotrichum community which will tend to dry the surface and form the characteristic white film seen in some of the pictures here. The development of this surface community produces the enzymes which will gradually ripen the cheese causing the rather solid curd like structure of the new cheese to develop into a soft custard like paste of the fully ripened cheese. The cambium layer on the outside will contribute a rather aromatic character of smoked meat and piney resin.

Cheese Making Supplies

Related Products

You May Also Like