Crescenza Recipe

-

Yield

1 Pound

-

Aging Time

None

-

Skill Level

Beginner

-

Author

Jim Wallace

Crescenza Recipe Info

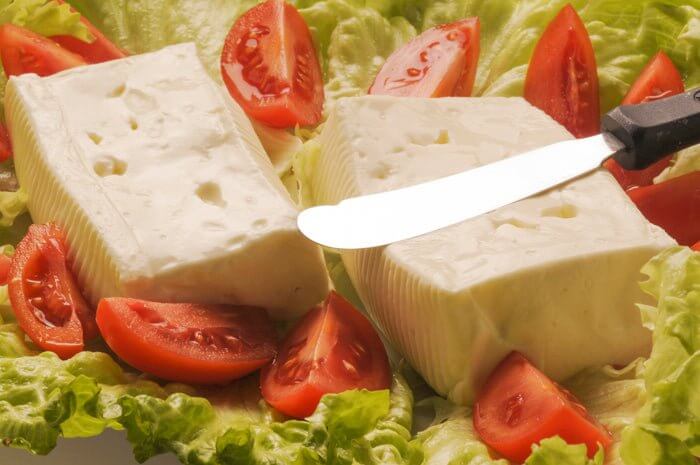

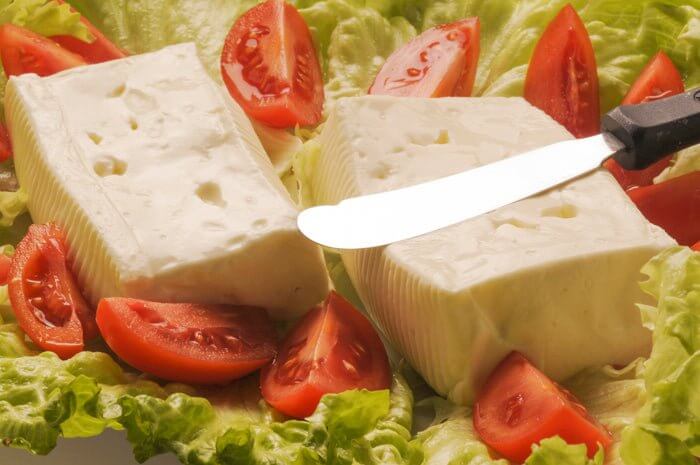

About Crescenza (Stracchino di Crescenza)

Serving and Pairing Crescenza

The Story of Crescenza Cheese

Variations and Modern Crescenza Making

Ingredients

Total price for selected items: Total price:

Instructions

A Recipe for making Crescenza in your Kitchen

The secret of this cheese is balancing the acid development with the correct moisture level in the cheese to have it ripen properly. You can choose to make it very moist and soft or a bit drier for firmer texture and a little longer aging.

-

Acidify & Heat Milk

Begin by heating the milk to 100°F (38°C). You do this by placing the milk in a pot or sink of very warm water. If you do this in a pot on the stove, make sure you heat the milk slowly and stir it well as it heats.

Once the milk is at 100°F, add the calcium chloride (1/4tsp) if using pasteurized milk.

-

Add Salt: The next step is rather unusual for most cheese, but for this cheese all of the salt will be added before adding any culture. Actually this is a bigger dose of salt than normal (about 2.5-3% at final cheese weight) but some of this will run off with the whey and the final cheese will retain the proper amount of salt (~2%).

For 1 gallon of milk this will be about 0.75oz of salt. Make sure this is well stirred in before adding the culture. The functional aspect of adding this now is that the culture, being somewhat salt sensitive, will work slower and thus produce lactic acid over a much longer time. Among other things, this slow acid will also slow the whey drainage and thus preserve the final moister of the cheese.

-

Add Culture: Now the culture can be added. Here I use about 1.5% of culture volume to milk volume. For 1 gallon this will be about 2 oz. of yogurt made from the Y1 Yogurt Culture. If you will be storing your finished cheese longer also add 1/64 tsp of C70 Geotrichum Candidum.

Once the bacteria is added a short rest of about 30 min. will allow the bacteria population to grow to a size suitable for the larger batch of milk.

Tip: I set a clock to 12:00 when I add the culture, so that this will give me my time reference for the entire cheese making session. This allows me to take the time info for reference in my make notes for each batch.

-

Add Salt: The next step is rather unusual for most cheese, but for this cheese all of the salt will be added before adding any culture. Actually this is a bigger dose of salt than normal (about 2.5-3% at final cheese weight) but some of this will run off with the whey and the final cheese will retain the proper amount of salt (~2%).

-

Coagulate with Rennet

Our next step is to add about 0.75ml (slightly more than 1/8tsp) of single strength liquid rennet. This should be diluted in about 50-60ml of cool non-chlorinated water.

The rennet should then be stirred in well with a brief up and down motion of the spoon/ladle for about 30-60 seconds to establish a complete distribution throughout the milk.

The milk now needs to sit quiet for 60 minutes while the culture works and the rennet coagulates the curd . The thermal mass of this milk should keep it warm during this period. It is OK if the temp drops a few degrees during this time. You will notice that the milk begins to thicken at about 18 minutes but give this the full time for a good firm coagulation. This is part of the process that controls the higher final moisture that does not readily drain from the cheese form.

Try to keep the milk at the correct temperature during the coagulation time. This is best done in a sink of water that is maintained a degree or so above the target temperature.

While waiting for the coagulation to complete, make sure you have sanitized the forms and draining mats. The arrangement will be from the bottom up:- Stiff board to make it easier to flip the cheese mold and curd

- Draining mat to allow the draining whey to flow away

- Cheese mold

- Set aside an aditional stiff board and draining mat for easier flipping of the curd later

-

Cut Curds & Release Whey

-

First Cut: Once the curd has formed, it can be cut to release the whey.

Cut a vertical cross hatch of about 2-3" in size. Do not stir after the cut.

This will be allowed to rest for about 30 minutes while the cut surfaces heal slightly and some whey is released along the cut lines and above the cut curd. The whey should be a nice clear yellow/green.

-

Second Cut: This is the phase at which you can determine the moisture of the final cheese. The larger cut at this point will retain whey for a higher moisture cheese. The cutting at this point needs to quite gentle so as not to disturb the first curds cut any more than needed. Remember small pieces yield a drier cheese.

The size we want here is somewhere between (5/8-7/8") a hazelnut (drier) and a walnut (moister). The cut can be made with a combo of knife and spoon. Minimal stirring should be done at this point. What we should see in the final cut is a nice plump piece of curd containing a good amount of moisture. The stir should be kept to a minimum at this point, just enough to keep them separated.

When you have achieved the final curd cut size, they should be allowed to settle with an occasional gentle stir every 5 minutes or so to keep the curd mass from consolidating. This should take 10-15 minutes.

As you can see by the above description that there is a little subjective decision making in this cheese, depending on what you want. A few trials with good note taking along the 'whey' should get you what you like the most for your Crescenza.

The important thing is to keep the cutting and stirring gentle and to a minimum to avoid breaking these very fragile curds.

Once the final curd is ready and the curds have settled we can remove the whey from the surface.

Note: There is no cooking phase to this curd handling, the curd is simply cut and stirred briefly but gently. Then allowed to settle under the whey while acid develops and more whey is released as described above.

-

First Cut: Once the curd has formed, it can be cut to release the whey.

Cut a vertical cross hatch of about 2-3" in size. Do not stir after the cut.

-

Mold Curds & Drain Whey

The curds can be transferred carefully to the molds along with their remaining whey as shown here.

The curds need to be kept warm 75-78°F for the next 4-6 hours to encourage the free whey to drain AND the culture to keep slowly converting lactose to lactic acid and hence more whey to be released. In Italy this is called the 'Stuffatura' or steaming phase. This is very important to a successful Crescenza cheese.

First Turning: The form can be flipped as soon as all of the curds have been transferred by placing the 3rd mat/board on top of the draining form thus making a sandwich of these with the mold. The mold is then quickly flipped thus forming a nice consolidated new top surface.

2nd Turning: Allow this to continue settling for about another 60 minutes before flipping again. As noted in the pics below, the draining curd will be much lower in the molds. Make sure the cheese stays warm during the draining.

3rd Turning: The cheese can be turned a third time in another 60 minutes and the cheese will sit lower yet in the form, the difference in height being the whey that has been released.

Following this the cheese can be allowed to rest overnight in the mold.

-

Finishing

The next morning the molds can be removed and the final cheese will be about 1.25-1.5" in height. My guide for final moisture is about 18-20%. This means that the weight of the final cheese is only18-20% of the milk used.

The final cheese with the form removed will be VERY moist and still quite jiggly, almost like pudding, however it does have a pretty firm structure as shown in the pics below. Although this is a very moist cheese it is still quite easily sliced.

There is no salting of the final cheese because all of that salt was added to the milk at the beginning. The cheese needs to move to fridge temperature at this point.

There is still a substantial amount of whey containing lactose and the cheese will continue to produce acid until the cheese reaches fridge temperatures in another 6-8 hours.

-

Storing

In the fridge, the cheese should be placed in a covered plastic container with a mat to allow any draining whey to run off (remember its still working until it reaches the fridge temperature). Turn the cheese and remove any residual whey as it collects.

The cheese should be ready to eat in 3-5 days, but will continue to soften over time. It is VERY spreadable. You will also see the cheese spread and even crack at the surface as it ages. This should probably be consumed within 7-10 days but I have not found that to be a problem here.

Note: Crescenza comes from the Italian ‘crescere’ which translated means ‘to grow’ and refers to the spreading of the cheese as it ripens and softens more. This also may refer to the tendency of the cheese to swell (like rising bread) and even split when left at warmer temperatures.

Cheese Making Supplies

Related Products

You May Also Like