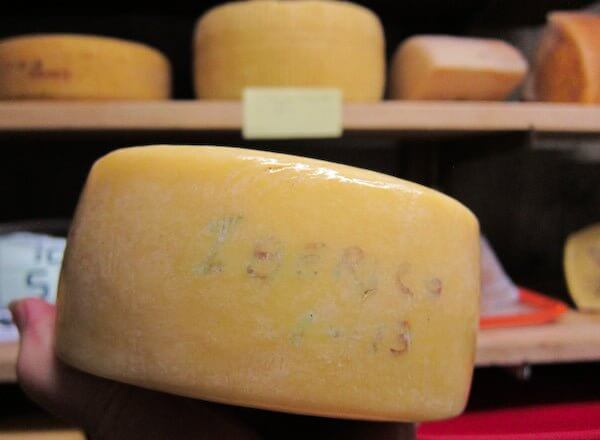

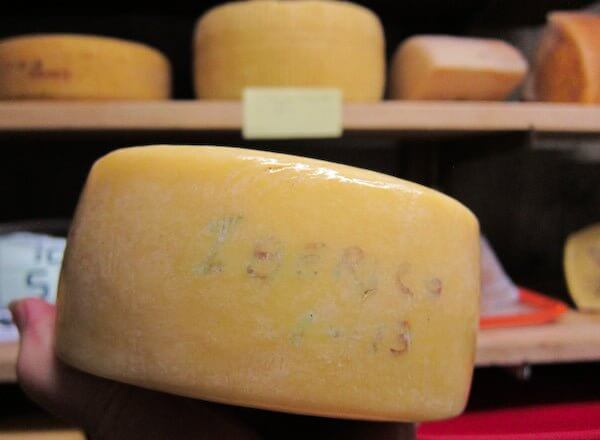

Hispanico Cheese Making Recipe

-

Aging Time

~2 Months

-

Skill Level

Intermediate

-

Author

Jim Wallace

Hispanico Cheese Making Recipe Info

Spanish Cheese Making

A History of Hispanico Cheese

About Hispanico Cheese

Styles and Cheese Making Process

Ingredients

Total price for selected items: Total price:

Instructions

-

Acidify & Heat Milk

Begin by heating the milk to 86F (30C). You do this by placing the milk in a pot or sink of very warm water. If you do this in a pot on the stove, make sure you heat the milk slowly and stir it well as it heats.

Once the milk is at 86F, the culture can be added. To prevent the powder from caking and sinking in clumps, sprinkle the powder over the surface of the milk and then allow about 2 minutes for the powder to re-hydrate before stirring it in.

Allow the milk to ripen for 30 minutes before adding rennet.

-

Coagulate with Rennet

Then add about 1/2 tsp (2.25ml) of single strength liquid rennet.

The milk now needs to sit quiet for 30-40 minutes while the culture works and the rennet coagulates the curd. The thermal mass of this milk should keep it warm during this period. It is OK if the temp drops a few degrees during this time. You will note the milk thickening at about 15-20 minutes but wait for the full firmness.

-

Cut & Stir Curds

The curd cut begins as a large vertical cross cut of about 1" squares. Let this rest 1-2 minutes while the whey shows between the cuts. This will firm the curds a little more before the next cut.

Then, use a knife for vertical cuts and spoon or ladle to reduce the curd to rice grain size.

I find that a kitchen whisk with as thin a wire as you can find works best for cutting these smaller curds, similar to alpine and parma style cheese. I use this slowly at first and then increase the cutting speed as the curds are reduced in. As the curds become very small, a rather vigorous cutting speed can be used. This may take a while to get good at so do the best you can. Make sure you reach to the bottom and in all corners to get the curd cut to as even a size as possible.

This should take about 10 minutes for cutting followed by another 20 minutes of stirring to firm the curds before increasing the heat.

The curds will begin as very soft grains with little to no structure and then as they are stirred and then heated they will firm up, becoming smaller, until they stand as separate pieces.

-

Cook Curds

Now it is time to begin drying out the curds. This will be done by increasing the heat slowly to 97F (36C). The heat needs to be increased slowly at about 2F (1C) every 5 minutes at the beginning. The total cooking time will be 25-30 minutes and may be extended to another 10-15 minutes if the curds are still soft.

The final curds should be cooked well through and should be examined to make sure that enough moisture has been removed. A broken curd should be firm throughout and the curds should have a moderate resistance when pressed between your fingers.

When this point is reached the curds can be allowed to settle under the whey.

-

Drain & Mold Curds

Once the curds settle to the bottom, the whey can be removed to the curd level with a colander and bowl.

The curd then needs to be consolidated to one side of the vat under the whey. I find the easiest way to do this is with a piece of our plastic matting (medium mesh) , but you could do this with a piece of muslin cloth. Use the cloth or mesh to drag the curd mass up against one side and consolidate with a light hand pressure into one compact curd mass. Next, find a plate or pan lid (sanitized) and use this with a little weight of about 8.5 lbs (this just happens to be the weight of that gallon of whey you just pulled off).

This weight only needs 20-30 minutes, after which the whey can be drained.

All of this is done to minimize the mechanical openings and to ripen the cheese to a good even and smooth paste.

The dry curd mass can now be transferred to your sanitized mold lined with butter muslin. If it is too large for the mold, just break it into several LARGE chunks and firmly pack into the mold with a firm hand pressure.

-

Pressing

for pressing we should begin very light and slowly increase the press weight to a moderate level:

- 30 minutes at 10 lbs

- 60 minutes at 20 lbs

- 5 hours at 30 lbs

- Overnight no weight

The rate of whey running off is simply a matter of drops or a thin stream of whey being released. This is a good rate of whey removal during pressing and will slow even more as the residual free moisture is released. The form should show tears of whey weeping from the form very slowly. When this stops, you can increase the weight slightly.

The cheese should be removed from the press, unwrapped, turned, re-wrapped, and put back into the press at the above intervals to assure an even consolidation. At each turn, you will notice the cheese has formed a smoother surface and rests lower in the mold. During the final rest, turning and re-wrapping several times will promote a nice smooth rind.

At the time of the molding, the culture has not reduced a lot of lactose and is still quite sweet (low acid - high pH) so try to keep the curd at 72-78F during the press time and then overnight. This slow production of acid which takes place largely after molding will develop a more elastic structure in this cheese. The next morning the cheese should have developed it's final acid and will be ready to be removed.

-

Salting

You should have a saturated brine prepared for salting this cheese.

A simple brine formula is: 1 gallon of water to which is added 2.25 lbs of salt, 1tbs. calcium chloride (30% solution), and 1 tsp. white vinegar.

The cheese now needs to be set in the brine for about 8-10 hours for this cheese which will weigh about 2.25lbs.

The cheese will float above the brine surface, so sprinkle another teaspoon or 2 of salt on the top surface of the cheese. Flip the cheese and re-salt the surface about half way through the brine period.

At the end of the brine bath, wipe the surface and allow the cheese to surface dry for a day or two before waxing or continuing with a natural rind. The surface will darken somewhat during this time.

-

Aging

The cheese can now be waxed for aging or for a more traditional surface, just turn the cheese daily and brush off any mold that develops. The rind will firm anddry over time and at about 1-2 weeks begin rubbing in a few drops of olive oil. This will give the cheese a very attractive surface and make the mold removal over time much easier. You will find that after a month or so the cheese needs less and less.

The cheese can then be placed into your aging space at 52-56F and 80-85% moisture.

The cheese can now be aged for 6-8 weeks and it will ready for your table but will improve with age up to about 6-8 months.

Cheese Making Supplies

Related Products

You May Also Like