Yorkshire Cheese Making Recipe

-

Yield

2 Pounds

-

Aging Time

~3 Months

-

Skill Level

Advanced

-

Author

Jim Wallace

Yorkshire Cheese Making Recipe Info

Yorkshire & Wensleydale Origins

What Makes Wensleydale® Cheese Unique

The History of Wensleydale Cheese Making

The Wensleydale Creamery Today

Ingredients

Total price for selected items: Total price:

Instructions

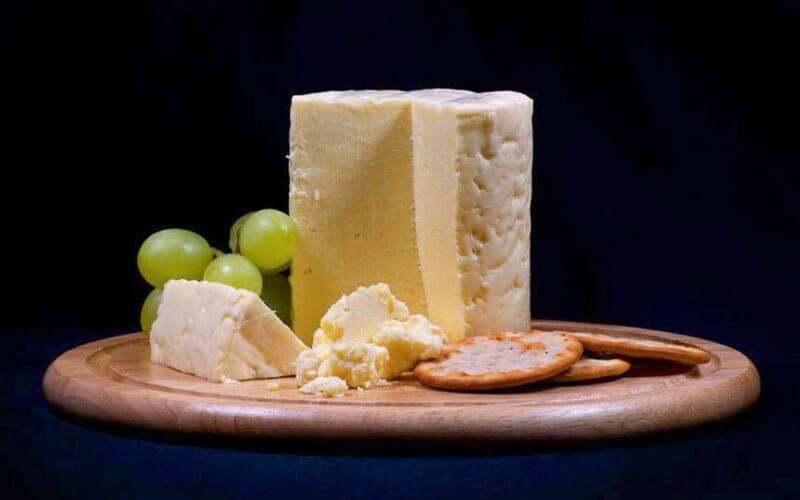

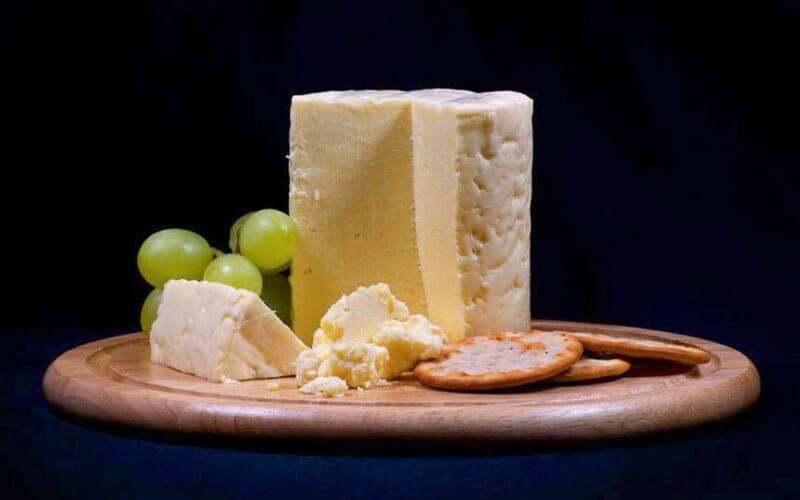

A Recipe for making a cheese in the style of the Yorkshire Dales

This cheese has been on my radar here for some time now and in the end I have managed to make my own version of a cheese that to me seems to fit the profile. The research has come from no less than seven different recipes gleaned from different sources ranging from the 1700's to modern times. What I can conclude from all of this is that what we are making here is our own version of a truly regional cheese that has come through history a bit scarred but none the less very alive.

As I have done in the past, I have photographed a larger make but will give a recipe for a smaller home scale cheese using 2 gallons of milk.

Make sure to start this cheese early in the day since it will take about 6.5-7 hours from culture addition to final salting

-

Acidify & Heat Milk

Begin by heating the milk to 86°F (30°C). You do this by placing the milk in a pot or sink of very warm water. If you do this in a pot on the stove make sure you heat the milk slowly and stir it well as it heats

Once the milk is at 86F the culture can be added. This cheese needs a long slow acid development and therefore less culture than usual. Use 1/2 pack of the C101 culture for this. It's easy to split using a clean piece of foil and a sanitized dry knife: dump the culture into a neat pile in the center of the foil and split it evenly in two. Use 1/2 for the Wensleydale and the other half goes back in the pack (roll it tight seal with an elastic band or tape and into another sealable plastic bag then into the freezer, use within 6 weeks).

To prevent the powder from caking and sinking in clumps sprinkle the powder over the surface of the milk and then allow about 2 minutes for the powder to re-hydrate before stirring it in.

The curd should be kept quiet to ripen for about 60 minutes.

-

Coagulate with Rennet

Next add about 1.25ml (1/4tsp) of single strength liquid rennet.

The milk now needs to sit quiet for 45 minutes while the culture works and the rennet coagulates the curd. The thermal mass of this milk should keep it warm during this period. It is OK if the temp drops a few degrees during this time.

You should notice the milk beginning to thicken at about 15 minutes but make sure to let it sit quiet for the full time until a firm curd develops.

While you are waiting for the set, this is a good time to sanitize your draining colander/pan and cloth as well as the forms.

-

Cut Curd & Release Whey

Once a firm curd is established, cut the curds to 1/2" pieces, then allow to rest about 5 minutes before slowly stirring to keep the curd mass from consolidating.

Then stir gently every 3-5 minutes. This should be gentle movement of the curds from the bottom of the pot upwards, just enough to keep from matting.

-

Drying the Curds

If the temperature has dropped by the end of the previous 30 minute stir, then heat slowly back to 86°F.

These curds will NOT be cooked like a cheddar cheese but instead will undergo a 90 minute slow stir to keep them moving slowly in a bottom to top direction throughout the pot. Essentially the warmth and slow movement will cause the whey to be released. This will dry the curds before draining the whey.

The final curds should be cooked well through and should be examined to make sure that enough moisture has been removed. A broken curd should be firm throughout and the curds should have a moderate resistance when pressed between the fingers.

When this point is reached the curds can be allowed to settle under the whey

-

Remove the Whey

The dry curds can now be transferred to a colander lined with butter muslin. Pull the cloth together and tie in a tight knot. Turn the bundle over onto this knot and keep warm for about 30 minutes. During this time the curd will be consolidating into a firm block. Due to the smaller size of this curd mass, I augment the weight with a board and about 1/2 gallon of warm water to help the curds come together.

As shown above, I use a plastic tub that I have punched for drainage using a hot nail.

-

Cut Curd Mass

The consolidated curd should now be cut into 2 inch blocks. Once cut, gather the blocks of curd in the cloth and tie in a bundle as before. Continue to keep them warm.

Over the next two hours open the bundle every 30 minutes and break each piece of curd in two and retie as before. This will be a total of 4 breakings and with the curds being broken should end with about 1/2 inch pieces for salting.

When the final bundle is open, the curds should be all well separated. If they have matted somewhat make sure that all curds are broken to about 1/2 inch and are easily separated. This step will prepare a dry curd with little moisture and ready for salting.

-

Salting

The final curd should now weigh about 2-2.25 lbs. Measure out the salt at about 1.5% of this weight (about 1/2 oz.). Sprinkle about half of this on the curds and mix it well into the curds until it is absorbed by the curds. Then add the other half of the salt. Mix in well again

-

Molding

The curds can now be packed into the form lined with cheesecloth using a firm hand pressure.

Once this is done, pull the cloth evenly out all the way around the mold to avoid wrinkles and creases. Then fold the cloth over the top of the mold as even as possible.

Set the follower on top of this and place the mold into a cheese press. You are ready for pressing the curds.

-

Pressing

For pressing we should begin with a small amount of weight overnight and then increase the next morning

- 12 hours at 5lbs (overnight)

- 5 hours at 20lbs (begin next AM)

- 12 hours at 40-50lbs

- 12 hours at 40-50lbs

The cheese should be removed from the press, unwrapped, turned, re-wrapped, and put back to the press at the above intervals to assure an even consolidation. At each turn you will notice the cheese has formed a smoother surface and rests lower in the mold.

The rate of whey running off should be very slow. The form should show tears of whey weeping from the form very slowly. When this stops you can increase the weight slightly.

The final cheese should be well consolidated at the end of this. If the curds still have openings or cracks appearing in the surface, then press longer and perhaps with more weight.

Note the various stages of curd consolidation as the cheese undergoes the pressing

-

Finishing & Aging

The cheese can now be waxed for aging. For details on waxing, please click here

The cheese can then be placed into your aging space at 54-58°F and 80-85% moisture.

The cheese can now be aged for 2-4 months and it will ready for your table.

For a more authentic finish to the cheese, you can opt to try applying a cloth bandage to the surface as show in the photo here. The details for this can be found on our cheddar page.

Cheese Making Supplies

Related Products

You May Also Like