Just Beginning Their Cheese Making Adventure

Pam and Ray Robinson are the fourth generation of Robinsons to work their farm. Ray grew up there. Nestled in the hills of central Massachusetts, it’s a lovely place to visit, even on a muddy winter day.

|

| The make room, aging rooms and packing room are in this side of the barn. |

|

| Inside the door there is a transition room, separate from the make room where boots are removed, etc. |

|

| The farm stand. |

|

| The Robinson’s house is connected to the farm stand. |

|

| The chickens have a nice view of the rolling hills beyond. |

|

| View from the farm stand. |

|

| Socks |

The Robinsons sell their own organic raw cow’s milk (at the farm only), grass-fed beef, organic eggs, seasonal vegetables and, as of four months ago, organic farmstead cheese. All of their cheese is washed curd with natural rinds and it is made with raw milk. (Of course, it is all aged more than 60days, as required by law.) In their farm stand, they also sell maple syrup, Sidehill yogurt, Westfield Farm goat cheese and, of course, our 30 Minute Mozzarella Kits (which add value to any retail establishment!).

Prior to all this, the Robinsons were struggling to make their living selling milk to a large cooperative. In 2003, they were getting $1.14 per gallon. That year, their daughter, Gina came home from college with an idea. She had learned about the benefits of raw milk and had noted that the selling price was $5 per gallon. She thought raw milk was the way to go but her parents weren’t convinced.

So, with four cows, she began selling and marketing raw milk. Within a short time, folks were driving from as far away as Boston to buy it. Her parents were impressed, so one thing led to another and within a few years, they had transitioned to selling organic raw milk from pasture-fed cows. (It takes one year of eating organically for a cow’s milk to be considered organic, but it takes 3 years for the land to be certified.) The complete story of this transition may be found in an excellent article about the Robinsons by Dazid Pazmino in Edible Boston.

|

| Under construction in 2010. |

After this, the next logical step was to make cheese. Pam and Ray wrote their business plan and crunched the numbers in 2009, planning to build their make room in early 2010. They did, of course, build it eventually in an existing barn, but it took almost 9 months and an extra $40,000 to do it. What was the problem? It was the plumbing.

In New England, agriculture has always been considered residential. In fact, the Robinson Farm lies in a residential district (as do most farms). Unfortunately, the Board of State Examiners of Plumbers and Gas Fitters decided that the farm would be commercial if the Robinsons were making cheese on it. This meant that the pipes (which are usually PVC in creameries) would have to be made of cast iron. (Iron is the worst choice for dairy purposes because the acidity in the milk causes pitting and rusting in the pipes.)

Cast iron pipes cannot be placed above concrete, so the concrete floors of the barn had to be jackhammered apart to accomodate the pipes. All of this cost the Robinsons time and money. They tried to appeal the decision, but eventually gave up and went ahead with their construction.

Their creamery is absolutely spotless and they go to great lengths to keep it that way. When I entered the barn, there was a green line painted on the floor. I took off my boots on one side and on the other side I put on rubber shoes, a white jacket, and a hat. Then, I entered the make room itself where I was asked to wash my hands.

|

| Shoes, coats and hats are provided for anyone entering the work area. |

Their vat holds 264 gallons. They bought it new because they couldn’t find one used. That was a major expense. Their Kadova molds were another significant investment. They hold 25 pounds each. (The Swiss cheese does better in big wheels, so they have adapted their other cheeses to fit these molds.) The first day I was there, they were only using 180 gallons of milk because this time of year, their 34 cows are not giving much milk. In the summer months, the cows are milked twice a day and the yield is much greater.

|

| When filling this vat, milk is pumped from the milking parlor directly to the pipes above. The elbow is removed, another pipe is fitted in and the milk pours directly into the vat. |

|

| 25 pound Kadova molds |

|

| Curd cutters |

|

| Pneumatic press |

Making the Cheese

|

| Adding veal rennet to the milk. (This batch will be Swiss cheese.) |

|

| Stirring |

|

| Checking the pH |

|

| Cutting the curd |

|

| Scraping the sides |

|

| Ray makes this look easy, but it can be hard on the back. |

At this point, I had to leave, so I came back again to see the rest of the procedure. On that day, Ray was making a brick cheese with less milk than he had been using in the pictures above. While he was cutting the curds, he carefully cleaned some of the curds off the bottom of the cutters which are sharper than they look.

When the curds are cut, Ray drains off the whey which gets taken by a neighboring farm for their pigs. As he works, he cleans his equipment.

|

| Draining the whey |

|

| Cleaning the curd dam which keeps the curds from going out with the whey |

Next, he packs the molds with curds, trying to get the same amount in each mold. This is a messy procedure, but fortunately the floor is tipped toward the drain.

|

| Whey pours out of the drain holes from the wet curds |

When the molds are full, the followers are placed on top and the curds drain as the cleanup continues.

|

| The vat tips (pneumatically) for draining the curds and for the final cleaning |

When he is done cleaning the vat (which he does thoroughly inside and out with cleanser), he turns the cheeses over and repacks them in the molds. Then, he piles them on the press. After 2 hours, he will turn the cheeses again and put them back in the press until later that night.

Aging the Cheese

When the cheeses have been pressed, they go into the brine bath in the first aging room. This is their only source for salt (it’s not added to the curds with these cheeses as it is with cheddar). The Swiss soak for up to 36 hours and the other kinds for longer. (The proprionic bacteria in the Swiss doesn’t like too much saline.) The brine room is 50-55F with 70% humidity. After the cheeses are brined, they all spend 4-5 weeks in that first room.

|

| Brine bath |

|

| Robinson Family Swiss in the brining room where they stay for 4-5 weeks |

The second aging room is 68-72F with 85-90% humidity. This room is only for the Swiss cheeses. The other cheeses go right from the first to the third room.

|

| Swiss in second aging room |

|

| More Swiss in second aging room |

The final aging room is 50-55F with 85% humidity.

|

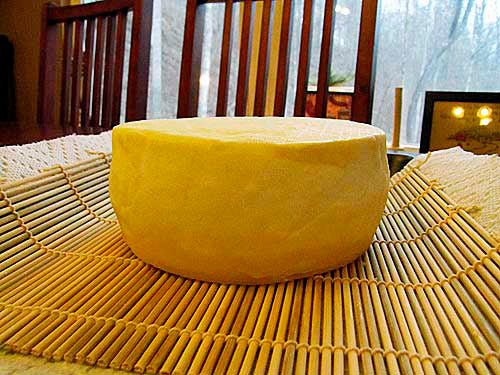

| A Barndance cheeses |

|

| Tekenink Tomme |

|

| A Barndance cheeses |

Packaging the Cheese

In the pictures below, Pam is shown cutting and packaging the cheese. Most of the time, however, she is busy with marketing, public relations, finances, inventory, employee supervision, the chickens and putting out fires. In other words, she wear lots of different hats!

So, (although they aren’t shown here), there are a couple of part-time employees who do most of the packing. They also help with the affinage (turning and wiping the aging cheeses). The Robinson’s cheese is sold in specialty shops, their farm stand and in farmer’s markets. It may also be purchased from their website. When you buy an uncut wheel online, the price is only $10/ pound and the shipping is free with a purchase over $100. (This is a great deal!) Otherwise, it is $22.25 per pound with a 3 pound minimum. At the farm stand, the price for cut cheese is $15/pound and at the farmer’s markets, it’s $17/pound.

Their signature product is their Swiss. I had actually never tasted a good Swiss before theirs so I was not prepared to like it. I cautiously bit into a piece of it, then quickly realized that it was absolutely delicious. There’s no comparison between it and the rubbery supermarket variety. I know when a cheese is good because I get tingly all over as I taste it and I was tingling!

Their second most popular is called “A Barndance.” This is equally delicious- smooth and mellow, a little bit softer than the Swiss. It’s modelled after the French “Abondance.” The natural rind adds a nutty flavor, as it does with the Swiss.

I haven’t tasted their Tekenink Tomme or their Hardwick Stone (an American brick cheese) yet because I’m still hung up on “A Barndance.” When I get into a cheese, I can’t separate myself from it until it’s all gone and I am definitely into “A Barndance” right now. You’ll have to taste the others yourself!

Raymond and Pamela Robinson42 Jackson RoadPO Box 94Hardwick, MA 01037(413) 477-6988email: info@robinsonfarm.org