It’s officially a tradition now – every year, in February, we post an update on Eric Olson’s incredible progress from home cheese maker to professional. To get caught up, check out these 2 articles:

1st article – February, 2017

Eric Olson’s Amazing Home Set-Up

2nd article – February, 2018

Eric Olson’s Amazing Make Room Updated

We left off last winter, and now Eric is about to start selling fried cheese from his new cheese truck. The cheese looks yummy and we really wish we were in Reno, Nevada right now!

Here’s Eric’s progress over this past year:

March, 2018

I’ve branched out a bit and have made my first blue cheese. Everything has gone great with it so far. I still have to put some holes through it and then let it mold for around 45-60 days.

I have also been getting some great yields from the sheep milk.

6 pounds 7 ounces of cheese from 4 gallons of milk.

April, 2018

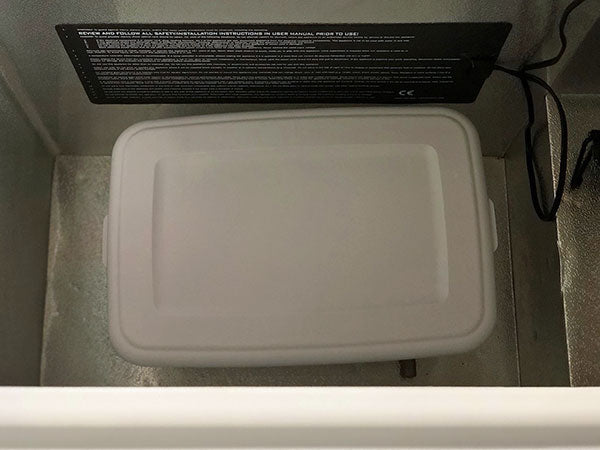

Here is what I’m using for the blue cheese. I’m holding it at 52F now. I will hold it there for around 30 days and then check the small block to see where it is at.

Doing a completely new cheese is exciting and the waiting makes it that much better.

One week later

It is turning blue.

It has been 24 days.

I think I will taste the small block at 30 days and then decide how much longer to let it ripen. My original thought was to ripen it at least 45 days. This part will be a bit tricky for me because I don’t know a lot about blue cheese.

May, 2018

It’s been 30 days so I cut the small block to give it a taste. It is very good but the cheese is still as firm as a Munster cheese would be. I think it needs a little more time, but I’m no blue cheese expert.

I am using a chest freezer with a temperature controller that lets me control the on and off of the compressor by choosing the temperature range, so I have been keeping it at 52F.

Now that I see there is a good amount of mold through the cheese, I have dropped the temp to 39F.

I added the mold directly to the milk along with the starter. I pierced the cheese to let oxygen into the cheese. The mold didn’t spread on the outside of the cheese because I dipped it in an anti-microbial after I poked it.

I am going to check it again in a week or so.

June, 2018

I had my plant inspection last Thursday and got the approval to make cheese. I am now fully licensed to make cheese but I still have to get my products tested for the nutritional information and get my labels approved before I can sell the cheese.

Here are some pictures of the finished make room. Now I can thaw one batch of milk and start it pasteurizing while I thaw a second batch of milk. As soon as the first batch is pasteurized, it can be moved to the cook vat while thawing a third batch of milk. The third batch can be thawed and heated to almost pasteurizing temp by the time the first batch is moved to the drain table and the second batch is moved to the cook vat.

Some pictures of my first finished blue cheese:

I will be selling blue cheese, cheddar, colby, possibly muenster and a cheese that my father was working on.

My plan for now is to sell the cheese locally out of my home and maybe to set up a food truck and sell at some of the local functions around Reno.

I can legally sell the cheese out of my home but there are some limitations with that. I will mainly manufacture at home and sell elsewhere. I have acquired licenses to sell the cheese in Reno and Sparks specifically.

There are locations where the food trucks all park one evening every week and a lot of people gather there to try new things.

I will mainly be selling the cheese by itself and the main focus will be marketing a deep fried cheese that my father was working on. I will be conducting a sort of test market to see how people here respond to the idea of a non-breaded fried cheese. I am going to start by offering samples to get our name out there and selling some cheese as well.

If there is a good response to the cheese, I will then try to get it in a local bar or restaurant.

The cheese doesn’t melt and develops it’s own wonderful fried cheese crust.

After building a large cheese plant with my father and watching that dream fall apart, I decided to start this as a hobby plant with the ability to sell and market some cheese without relying on the product sales to keep us in business. This way it will stay fun and we will just see where it goes from there.

The main reason for all of this is to preserve my father’s idea for a truly fried cheese and to teach my brother how to make that cheese. Everything else that is possible with having our own cheese plant is just a bonus.

February, 2019

I just made a batch of the fried cheese with jalapeño peppers in it today. It is still in the press but I took a picture of it when I redressed it. I have made a small batch of it in the past with less peppers. I think this batch is going to taste great. I can hardly wait to fry some up.

I will be selling three versions of the fried cheese to start. Regular, onion and garlic and jalapeño. I also plan to sell hamburgers, hot dogs and french fries.

There are events all around the Reno area that will be good for selling, but I am trying to get into a specific group called Food Truck Friday. There is a park where a bunch of food trucks set up every Friday starting the middle of May and running through the end of September. There is live music and stuff set up for kids. It usually draws over a thousand people every Friday. If they accept my application, I will be starting in May.

I expanded my cheese system to the point where I can make three batches every day but will start with 2 per day for three or four days a week and sell Fridays and Saturdays. I will be able to make around 200 servings to start, with making 2 batches a day – four days a week. If I make 3 batches a day, I could get close to 300 servings.

I am using the food truck to get exposure for the unique cheese and as a test market so I can put together a good business plan and hopefully expand.

My brother Tyler and I will be doing everything to start with but I have another friend who makes some wonderful Mexican food which we may add to the menu after I get everything down.