I grew up in the Netherlands; just outside Gouda in a small old village surrounded by dairy farms, rivers and dikes. Gouda is the cheese capital of the country with a charming Thursday and Saturday cheese market.

My father was born on a dairy farm that was sold before my time. I spent the summers playing and working on my friends’ farms – feeding cows, cleaning, harvesting hay. My uncle was a cheese monger and cheese was always there.

After high school, my career took some interesting twists; I left for the city to study, I worked some years for an American pharmaceutical company and suddenly I was driving safaris in Africa for 5 months a year, guiding trekking tours in Latin America and visiting Mayan ruins in Guatemala for the other months.

Cheese was never part of my career path but, because of my travels, I developed a growing interest in food and local flavors. I met my wife on a mountain in Peru –fifth generation Torontonian and the reason I ultimately landed in Canada.

Today, besides giving cheese workshops, I enjoy being a private tour guide for small parties – 2 to 6 people to Niagara Falls, Toronto, Mennonite communities in the countryside. I work a lot with the high-end hotels in Toronto and with travelers who can afford something different than a hop-on hop-off bus, what is fun in its own way. I like to call it ‘A bit of magic and a little surprise’ every single day; I never know who shows up in the morning and the magic is to have them leave happy in the afternoon.

All went well till Covid 19 hit the world.

There are not too many people who can say that Covid 19 had a positive influence in their life. For me, this was the case in a certain way. The year the pandemic hit, Conestoga College in Waterloo started the first professional training in Ontario. They recognized a shortage of professional cheesemakers in Ontario and built the program to fill the gap. I jumped right on it.

A full year of learning cheese at college level. Because the early programs were done in a remote setting, we got trained by some of the best cheesemakers in Europe, Quebec and Ontario. Nobody traveled and courses were taught from dairies in Germany and kitchen tables in Quebec. (For program info – Professional Cheese Making | Full-time | Ontario College Certificate (conestogac.on.ca))

Closer to the end of the course, plenty of practice was done, to balance the program, and yes, companies and artisan cheesemakers were recruiting before we finished the program. It was the best thing that the pandemic could offer me to survive two years of being out of work.

I did some additional courses with the University of Vermont to follow up on some areas and cheese got the better of me.

After my study, I had many opportunities to start at artisan dairies and I landed at Mountain Oak Cheese, a Gouda cheese producer, which gave me great experience. After working there, I recognized that my talent is in teaching and infotaining while experimenting with cheese.

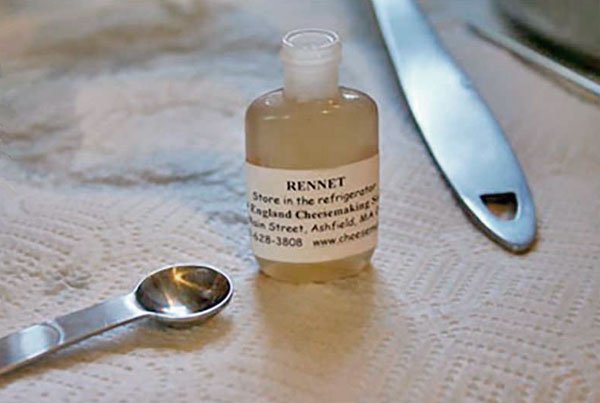

Early 2022, I started to offer private cheesemaking classes in the Toronto area. It is a unique experience where participants can step in at any level they feel comfortable with. The workshops are for people who like cheese and want to learn more, more experienced cheesemakers who would like to do better and even executive chefs calling me for a quick training in mozzarella. Two to 6 people in a private workshop for an afternoon of good stories, making cheese and of course a lot of tasting, smelling and a bit of pairing with some local wines.

Of course, it is not possible to push a year of knowledge in an afternoon, but it works. As an artisan cheesemaker and a communicator, I am having much fun being part of and building this new and growing community of local cheesemakers. A bit of magic and a little surprise with every workshop. People are excited and want to learn more about a simple food with so many variations.

I do most of my workshops in my home kitchen and on location at the participant’s home. I prefer this personal contact more than remote classes. I don’t do online courses for now. I find it hard to get the logistics right with the ingredients, the cultures and the molds. There are many good online videos available, and I don’t believe that I have to add more to it.

After a workshop, I ripen the cheeses for the first weeks in my own cave before I send them to the participant –that little surprise after some weeks, just when you forget.

A few of my cheeses:

Blue By You recipe from cheesemaking.com. Fun Experiment, very tasty

My press:

I am thinking of building a bigger wooden press for heavier weights, but this is still a work in progress. It fits two molds at the same time.

My cave:

My cave is a temperature controlled cold storage in the basement of my house – 20 x 4 x 7 feet. It doubles as a wine cellar.

I built this 10 years ago and it works well; the temperature is very well controlled year-round with a cooler. I have some issues with the varying humidity levels when there are different kind of cheeses in there that require various humidity levels, but by using individual boxes for ripening in different corners of the cave I can control this quite well.

The bottom cheese is a blue cheese in a blue cheese foil. I left it there temporarily. Because the Goudas are all waxed, I was hoping that the spores wouldn’t travel – and, luckily, they did not.

The cave, wine cellar is a birthday gift for my wife. For one of her birthday’s, she wanted a party but no gifts. I asked all her friends to bring a bottle from a year with meaning.

Other hobbies:

Between May and October, my wife and I try to spend as much time as possible on Lake Ontario. We sail a 32 foot Hunter which is good for overnight and weekend travel. We try to pack up on Friday or Saturday morning and we return home on Sunday. The boat is parked 10 minutes from our house and it is a perfect getaway from daily life.

Every cheesemaker knows that cheeses need to be flipped and washed, so logistically it can be challenging sometimes but we enjoy it.

Our other hobby is food; a good homemade meal or a visit to a new restaurant in the city. Julia Child has a chair at our table.

Cheesemaking Classes Toronto

https://www.cheesemakingclassestoronto.com

416-659-4244

leon@CheeseMakingClassesToronto.com