-

Boost Your Gut Health with Homemade Yogurt

There’s something so satisfying about turning a simple jug of milk into rich, creamy yogurt. It’s...

-

How to Make Cheese at Home: Beginner’s Guide

Have you ever wondered how to make cheese at home? Good news—you don’t need a barn, or a science ...

-

Parmesan vs. Romano: Differences, Recipes and Cheese Making Tips

Lessons from the Masters in Italy

Cheese is culture—literally and figuratively—and few cheeses ca...

-

Ingredients for Cheese Making

It's easy and fun to make cheese at home. When starting out, there are three basic compon...

-

Equipment for Cheese Making

It is easy and fun to make cheese at home. When starting out, there are three basic compone...

-

How to Make Cheese

It is easy and fun to make cheese at home. When starting out, there are three basic compone...

-

Cheese Waxing FAQ: How to Wax Cheese for Perfect Aging

Learn How to Wax Cheese

Looking to seal in flavor, lock in moisture, and keep unwanted mold at ba...

-

Rennet for Cheese Making: The Ultimate Guide to Types, Techniques & Troubleshooting

Welcome to your go‑to guide on rennet—the magic enzyme that transforms fresh milk into the cheese...

-

Draining Soft Cheese: Tips for Creamy, Delicious Results

Draining is a crucial part of soft cheese making—it directly affects your cheese’s final texture,...

-

Cheese Making pH Guide: How to Test and Control Acidity for Perfect Cheese

Understanding pH in Cheese Making: A Beginner-Friendly Guide

When it comes to making cheese at ho...

-

How to Store and Age Cheese in Brine

Learn how to properly store and age Feta, Mozzarella, and other Mediterranean style cheese in a l...

-

Learn About Cultures for Cheese Making

Some of the top questions we receive about cheese making have to do with cheese making cultu...

-

Finding Good Milk For Cheese Making

When trying to find good milk for cheese making there are a few things to consider and s...

-

The Evolution of Milk For Cheese Making

Most milk comes from cows and we’d like to think they are all out on pastures eating gra...

-

Affinage Cheese Course in Vermont

Affinage is the final phase in the life cycle of cheese. This is where the fresh pressed curd ...

-

Making Traditional Saint Nectaire

This article details how Saint Nectaire is traditionally made in the Auvergne

The farms where ...

-

The Spanish Cheese Sessions at UVM

Recently I spent a few days at the VIAC program on Spanish cheese. If they had to pick one p...

-

Learning About Parmigiano-Reggiano in Italy

Over the past several years I have spent a good deal of time visiting cheese makers around t...

-

Slow Food Festival in Bra Italy 2007

In Sept Jim Wallace (our cheese specialist) spent another 2 weeks visiting traditional cheese ...

-

Making Cheese in School

Cheese Making in Kriss Guptill's 5th Grade Classroom

Yes, that is right, learning can be f...

-

Laurie Higgins Making Cheese

This Article was Contributed by Laurie Higgins

Quick Tips for Home Cheese Making

Qu...

-

A Guide to Cheese Tasting Terms

Corky

Firm, hard, tough consistency, hard to break in fingers. When it breaks it does s...

-

Ways to Use Whey

Learn About Whey

Ways to Use Whey

.

Learn About Whe...

-

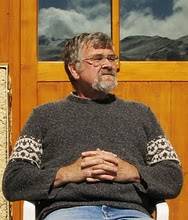

Jim Wallace

Meet a Cheese Making Guru

Tell us a little bit about your background

It has been a long ro...

-

Andrea Lewis

A True Home Cheese Maker

Andrea is a new startup cheese maker and what drew her to my atte...

-

Sister Joanna

The Monastery of Saint Nektarios in Doridos, Greece

Sister Joanna leads the sisters of t...

-

Terry and Linda Clapp

Little House Cheeses

This is true Home or Farmstead cheese making on a small scale.

Just t...

-

Cheese Makers Traveling Through Spain

This is my first trip to Spain for this so it shows a lot of how I go about making contacts. I...

-

Cheese Makers Traveling Through Italy

Susan Marquis from Arlington VA. has been a cheese lover and home cheese maker for quite some ...

-

Labneh Cheese Making Recipe

This recipe was sent in from Ursula Weiland in Knoxville TN.

Ingredients

1 gallon whole milk

3 ...

-

Queso Fresco Cheese Making Recipe

This is a fairly easy cheese to make in the kitchen. Exploring different cheese varieties can lea...

-

Problems with Ultra Pasteurized Milk

Problems with Ultra Pasteurized milk (UP) and how it affects 30 Minute Mozzarella Cheese. Unfo...

-

Milk and How it Has Changed

For years we have been told of the benefits of milk.

Milk builds strong bones

A milk mustache...

-

Cheese Makers Traveling Through Republic of Georgia

A few years ago, Ricki had the pleasure of visiting the Republic of Georgia, formerly part of ...

-

Yogurt Cheese Recipe

Yogurt Cheese may be made simply by draining the whey out of you yogurt. Understanding the proces...

-

Shankleshe Cheese Recipe

Shanklish, the word is either derived from Arabic or Turkish, I'm not sure.This cheese is great...

-

Saint Maure Cheese Making Recipe

A soft Goats milk cheese, shaped in an elongated cylinder or log. While youre experimenting with ...

-

Queso Blanco Cheese Making Recipe

Queso Blanco is a South American cheese similar to the Indian cheese Panir. It is an excellent co...

-

Ostkaka Cheese Making Recipe

This is a Swedish, Scandinavian, dessert dish, traditionally served at Christmas. Not really cus...

-

Lemon Cheese Recipe

This rich and delicious cheese may be made in the evening and will be ready to spread on hot cro...

-

Latvian Easter Cheese (Pashka) Recipe

Oma's Pashka submitted by Brent Alderman Sterste

My father's family is Latvian and we make a swee...

-

Juustoa Cheese Making Recipe

This Finnish, squeaky cheese recipe from Eleanor Miller in MI. It is eaten in cut pieces put into...

-

Oma's Janu Siers (John's Cheese)

Submitted by Brent Alderman Sterste

Traditionally made for the summer solstice - the longest day...

-

Guban Cheese Making Recipe

This is a Lebanese cheese using the simplest of ingredients. This finished cheese may be used in ...

-

Fromage Blanc Recipe

Fromage Blanc is a wonderfully creamy cheese that may be used in place of cream cheese in any re...

-

Farmers Cheese Recipe

There is a lot of variation in this white cheese because each person makes it slightly differentl...

-

Edam Cheese Making Recipe

Traditionally a Dutch cheese, made with partially skimmed milk & eaten when young. This chees...

-

Cup Cheese Recipe

This is a Pennsylvania Dutch Cheese made by the Amish and Mennonites since before the time of the...

-

Creme Fraiche Recipe

Creme Fraiche is one of those dairy delights that you try to eat just a little of but once you ta...

-

Clotted Cream Recipe

This is a specialty of Devon and Cornwall in Southern England. It is made from rich cows milk of ...

-

Home Cheese Maker Spotlight: Bernard’s Feta-Style Cheese with Kefir

We love hearing from home cheese makers who are finding creative ways to make delicious cheese in...

-

Curds, Goats & Gratitude: Life on Bluebird Meadow Farm

The First Goat, The First Cheese

Eighteen years ago, on a quiet stretch of land in Ada, Michigan,...

-

5 Fresh Spring Cheeses to Make at Home | Easy, Seasonal Cheese Recipes

Spring: A Season of Renewal (and Cheese!)

Spring is a season of beginnings. The days grow longer,...

-

Good Cultured Cottage Cheese: Fresh and Healthy

What Is Cultured Cottage Cheese?

Cultured cottage cheese is a fresh, creamy cheese that’s natural...

-

Kristy Foster in Yorba Linda, California

Kristy Foster and ?

If you live near Yorba Linda, CA (35 miles southeast of downtown Los Angele...

-

Leon Graafland in Toronto, Ontario, Canada

Leon Graafland in the tulip fields, 20 miles outside Gouda.

I grew up in the Netherlands; just ...

-

Which Rennet is For You?

Submitted by Kate Johnson and Kelly Liebrock of The Art of Cheese in Longmont, CO

February 21, 2...

-

Pictures from the Winter Fancy Food Show, 2023

Colleagues Ritz Guggiana (RG Consultants) and David Viviani (www.vivianimarketing.com)

Ten year...

-

Rita den Otter in Duncan, BC, Canada

Rita with her old Springer, Farley (14 1/2) and her pup, Abby (4 months) on a camping trip to Qu...

-

Andres Schneiter in Maple Ridge, British Columbia, Canada

Andres Schneiter with his Raclette

If you’re on our mailing list at cheesemaking.com, you’re fa...

-

Celso David Viviani in San Francisco, California

David Viviani at a reception for President Sergio Mattarella of Italy, at San Francisco’s Fairmo...

-

Kylie Carnegie in Melbourne, Victoria, Australia

Kylie with Rémy, her 18 month old Schipperke.

Kylie is just starting her cheesemaking adventure...

-

Fat Sheep Farm in Hartland, Vermont

Todd Heyman and Suzy Kaplan of Fat Sheep Farm

When Suzy Kaplan & Todd Heyman decided to get...

-

Marybeth Bullington's Orange-Walnut Holiday Cheese

Marybeth’s fabulous holiday cheese.

Good news! It’s not too late to make cheese for the holida...

-

Gift Ideas for Cheesemakers and Cheese Lovers

Pin, $2, teepublic.com

The giving season is coming up! It’s a little early but we think it’s a...

-

Cheesemaking Classes in the U.S. (Current)

Sarah Carroll at her Cheesemaking 101 workshop at New England Cheesemaking Supply Co.

We first...

-

Yoel Blumberger: On the Role of Cheese in Israel

Yoel Blumberger making Camembert

Yoel lives in Tel Aviv where he belongs to a group of cheesema...

-

Grant Fritch in Lansing (Okemos), Michigan

Grant Fritch

It’s always a surprise when we delve into a cheesemaker’s life and discover talent...

-

Yoel Blumberger: Camembert de Normandie AOP and the Flocculation Point Method

Picture by Yoel Blumberger. Sources: freeworldmaps and Dairy Products of France

In this arti...

-

Ivy Netzel in Gourley Township, Michigan

Ivy Netzel, making kefir

Ivy’s Story

I live in a quiet little hamlet called Jam Dam (unincorpor...

-

Yoel Blumberger: Cheesemaking Group in Israel and a Recipe for Castelmagno

Part of the group (with Castelmagno cheese) in front of a dairy high in the Italian Alps. Yoel i...

-

Hilda Elena Thielen in Marietta, Georgia

Hilda Elena Thielen

Hilda loves to cook with natural/minimal ingredients so cheesemaking is a p...

-

Imran Saleh in Pakistan - Camel Milk Cheese

Imran with a few of his artisan cheeses.

This is our 9th post about Imran since 2013. Since we...

-

Kathy Lynch in Queensland, Australia

Kathy Lynch in her studio

I live on 45 acres of beautiful land on the Sunshine Coast with an a...

-

Erol Sozen in Bloomington, Illinois

Erol Sozen

Erol comes from Turkey, a country where cheese is highly valued. Most of the cheese...

-

Dennis Woods in Portland, Oregon

Dennis with Tomme, after light press

They say if you want to get something done, ask a busy per...

-

Upcoming Cheese Festivals (Current)

Ricki Carroll (The Cheese Queen) at the Festival of Cheeses in 2015. This used to be the last e...

-

Maureen Blais-Gestrich in Sarasota, Florida

Maureen with Butterkase, Dunlop and Red Leicester on the press, Mountain Tomme on the platter an...

-

Making Cotija (Mexican Parmesan)

Lately, it seems like every recipe I see online and feel like making has Cotija in it. The corn ...

-

Vivian Lucero's Trip to the California Artisan Cheese Festival

Cheese please!

In 2019, we had the pleasure of interviewing Vivian – Vivian Lucero in Otis, Ore...

-

Hal Wentzel in Niagara, Wisconsin

Hal pointing to an apricot blossom a few weeks ago. The trees were just planted last year.

In ...

-

Jennifer Rollins in Sydney, Australia

Jennifer in her kitchen with a couple of vacuum packed cheeses and a tomme.

Jennifer seems to b...

-

Rhonda Bates in Frisco, North Carolina

Rhonda with Earl and Louise

Rhonda is a professional artist with many talents. When she was yo...

-

Molly Brown in Altoona, Pennsylvania

Molly at left with her grandmother, mother, and dog Muffin.

Molly Brown is no stranger to adven...

-

Whoops! Cheese Making Disasters

Molly Brown in Altoona, PA told us her first bandage wrapped cheese, a Lancashire looks worse th...

-

Shirley Hampshire in Kingston, Michigan

Shirley Hampshire

Shirley and her husband, Randy have 6 grown kids and 9 grandchildren, so far....

-

Gert and Connie Kok in Pretoria, South Africa

Gert & Connie Kok

South Africa is a long way from most of us. However, the internet brings...

-

Keith Stuart Phoenix in Warboys, Cambridgeshire, UK

Keith Stuart Phoenix

There are a lot of good things that came out of the Covid lockdown. Many f...

-

Deb Pero in New Boston, Texas

Deb told us these little guys are the reason she moved to Texas. (They’re not required to do fa...

-

Alan Stables in Colombo, Sri Lanka

Wishing you all the best!

To all cheesemakers – check this out if you sell your own cheese. Th...

-

Paulette Walker in Cincinnati, Ohio

Paulette with her Gorgonzola Dolce, Bel Paese, and Blue Stilton

When I first contacted Paulette...

-

Chris Harris in Springfield, Belize

Chris with a Wensleydale

In 2013, I had the opportunity to spend 5 days in Belize at Ian Anders...

-

Zorana's Queso Llanero (Venezuelan Hard Cheese)

Zorana Marquez

Zorana lives in Humble, Texas. We interviewed her a few weeks ago (click here) ...

-

Coreen Beaulieu in North Monmouth, Maine

Coreen with her daughter Moe! (University of Maine, Farmington Beaver Mascot – Chompers).

I li...

-

Fred Schenkelberg in Los Gatos, California

Fred on Dec 16th holding an Emmental that is done with warm aging and heading into the cave to m...

-

Sherrie David in Goldfinch, Texas

Sherrie and her husband, Forrest

Sherrie lives “Deep in the Heart of Texas” in a town so small,...

-

Michelle Becker in Toledo, Oregon

Michelle Becker

How we came to interview Michelle …

The Cheese Queen is known in kingdoms near ...

-

Jonathan Butlin in Northampton, England

Jonathan Butlin

We have actually found a cheese maker who used to play in a heavy metal band. ...

-

Zorana Marquez in Humble, Texas

Zorana Marquez in October, 2020. Photo by: Marco Chacon @mcfotologist

Zorana’s Story

I am in m...

-

Camille & John Bock in Willis, Texas

Camille & John Bock

Goodgrass Farm

We get a lot of questions about where folks can find goo...

Sr. Gertrude lives at the Abbey of St. Walburga in Virginia Dale, Colorado.

Sr. Gertrude lives at the Abbey of St. Walburga in Virginia Dale, Colorado.