Martin (right) at the Saddleworth Wine Vault which is owned by Julian in the picture. The coin in his hand was a token gesture as he was giving away a few samples of his cheese to customers on a Saturday morning.

Martin’s Story

I am based in Lancashire at a village called Uppermill.

Photo from Wikipedia

My house.

Front of the house.

Back yard.

My home (built about 1800) has a cellar that would have been used in those days to store dairy and salt items (I guess), so now it is maturing cheese all those years later.

3 batches of Camembert.

I and my family love cheese – it being the main event at special mealtimes. This and my enjoyment of cooking, often in a “I wonder what would happen if” style, had me homing in on trying what I thought would be impossible for a mere mortal and having heard that “blessed are the cheesemakers.”

I bought Ricki Carroll’s book and after lots of reading and the purchase of a kit, off I went. My first surprise were the tiny moulds in the kit but I soon realized that not much cheese comes from lots of milk.

I am up to batch eighty now!

With a customer at the wine vault, sampling my cheese.

I keep a log of every cheese I make. It’s not very organized but I use it mainly to remind me of the ingredients and some tasting notes, if I remember.

In the back, I keep bits of things I pick up on the way – business cards, lists of cheeses I’ve had in a restaurant, etc. So, that’s how I know how many. It started in 2016, I see.

I get my pasteurized, non-homogenized whole milk from one of three local farms.

I have attempted a Cheshire, Lancashire, Goats, Havarti/Gouda, hard and semi-soft variations.

Feb 2019. They were a basic Cheshire style. The big cheese was made using my adapted Bain Marie food warmer.

Lancashire Style – 2/5/2019

Stilton-Camembert combination – 9/10/2020

A basic, Cheshire style semi-soft cheese made in a coeur a la creme mold for Valentine’s Day – 2/11/2019

At the moment I’m concentrating on Camembert which my victims say is the best of my efforts so far!

Camembert in the making. Draining in the moulds. Eventually the curd will be only a quarter of that height after the whey has drained away.

12/9/2020. Camemberts ready for their wax paper wrapping, then to mature for four weeks.

My first attempt at Camembert – 3/1/2019.

My vat

You can see the milk thermometer sits through the hole where the handle screws on normally so you can put the lid on to preserve heat and it’s in the middle of the vat.

To the side, I sit another one which measures the water and I’ve found that if I keep that at roughly 100F it works a treat at keeping the milk (4 litres/1 gallon in this vat) temp just right.

Another little tip I’ve learnt along the way is to use my Amazon Alexa as a timer – “Alexa, set a timer for one hour.” (No hands and fingers having to set times on separate devices.)

Temperature controller:

I did an experiment using a temperature controller to keep the water jacket at about 34C (93F). The tank held 16 litres (4 1/4 gallons) of milk.

It worked great and kept the milk temperature spot on for the hour or so needed. But, for goats milk, which can need 12 to 18 hours, it would be more useful.

My press:

I used three domestic chopping boards and some stainless M10 threaded bar and stainless nuts. I drilled small holes to allow drainage from the bottom of the moulds.

The initial filling is done with the board with the three large holes.

When the first turnover is wanted, that board is replaced by one identical to the bottom one.

Flipped…

The draining and turnover goes smoothly with the patties unsticking nicely and dropping without any drama.

Waxing

I find waxing the easiest way to preserve the hard cheeses. I’ve tried cloth binding, brushed with molten butter or lard but that was messy and time consuming.

I find though, that the 2kg (4.4 pounds) hard rounds I sometimes make are difficult to hold while each half sets prior to it’s next dip. One split in half and fell straight back into the molten wax!

Happily, no damage done. I find that about 90C (194F) gives the best glossy finish.

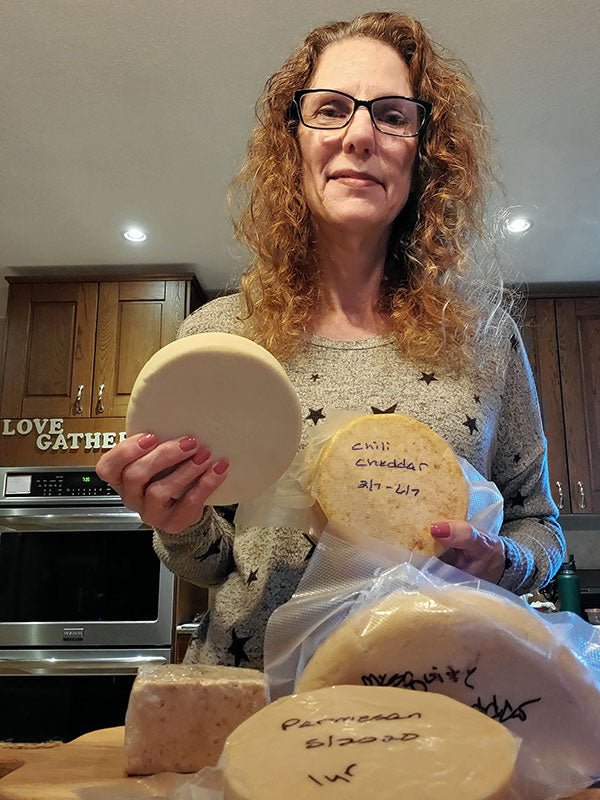

A cheddar-style cheese

My goals

My Facebook page was made up to share with my friends and family (https://www.facebook.com/Davenportscheese).

I do have a domain, too, but its off line at the moment. Both were started just in case I decide to expand and I wanted to establish a name for the idea.

Being a controls and automation engineer has me wondering how I can automate the process as a side line although I realize that’s not in the spirit of artisan handmade cheese.

So, my aim is to keep it non-commercial just now and enjoy the hobby and giving my cheese away. l have been badgered by my milk suppliers, a cheese wholesaler and the odd restaurant to grow. You will know, however, that it involves strict food standards, expense, food safe premises and so on. I don’t think I’m ready for that.

However, I did have some labels designed. Here is one of the ideas the designer came up with:

Other hobbies:

I take pictures of cheese counters in shops if I think they are interesting and when on my travels. That worries me 🙂