|

| Steve Murtaugh with his main Maoi – an Eastern Island Tiki |

Steve Murtaugh is a master home cheese maker. He sells his cheese at Farmer’s Markets in the Pittsburgh area. This coming summer, he plans to sell over 188 pounds of cheese!

Steve was one of the entrants in our recent our essay contest. He sent his essay with a lot of pictures included, as did a few other participants. For consistency, we judged and posted all the essays with only one picture.

Here’s Steve’s essay as it came to us originally, followed by research he did for us on Controlling Humidity in Your Cheese Cave:

My Cheesy Adventure

By Steve Murtaugh

After retiring at the end of 2010, I decided to get back to basics and renew more of the culinary arts of my grandparents. Having mastered most of the wine-making, cooking and baking arts, long ago, I decided to step back to the less technological skills. I started with basic, pickling and some limited

canning, moved on to making my own whipped creams and butters.

Near the end of 2012, I decided it was time for dabbling with cheese-making.

I started with acid coagulated cheeses; using, at various times, vinegar, lemon juice and even beer (or combinations thereof) as my acid. While running through the basic simple soft cheeses, I worked out a few spread varieties, a Velveeta-like cheese, and even developed some techniques to make simulated “sort-of” versions of slightly harder cheeses (My “Sortadella” Line…LOL)

|

| Bear (my nickname) Whiz “Sortadella” Mozzarella |

|

| Bear’s Beer-Whiz Bear’s Hot-Whiz |

|

| Some of my first month’s work Of course, naming some of these, required a twisted sense of humor! |

|

| A Peppery “Sortadella” Cheddar |

|

| Bear Whiz St. Pat’s Style Bear-Veeta |

|

| “Sortadella” Feta |

|

| Easter Cheese, Cirek, Sirec. Hrudka, Pashka, etc |

Having accomplished this stage of cheese-making, I decided to try my hand at semi-hard and hard cheeses. Tried Colby, Queso Fresca and Blanco, Gouda (and smoked version, too), and am currently aging some Swiss style cheese.

|

| Colby in the drying stage Queso Blanco, plated and Gouda (in press) |

|

| Gouda ready to hickory smoke … and waxed to age |

|

| 2 pound block of Swiss in the brine |

As my living space is consistently 71 F, my crisper is 48, and my garage 56 most of my “cave requirements are met. For protection and temp stabilization and humidity control I use a modified Styrofoam cooler, temp gauge, wire racks with draining mats and drip trays; shooting for a hygrometer in the very near future).

|

| My cheese cave |

When the grand-kids came to visit, earlier this month, we made our own yogurt and I also had them making their own butter!

Interview

I have a lot to share with you about Steve because he gave me quite a bit of good information about the coolers he uses for aging his cheese. He also conducted some experiments around the use of salt in controlling humidity in “caves.” He found that by putting salt in his aging coolers, he was able to maintain the perfect humidity. I posted his results a few weeks ago (click here).

I asked Steve a couple of questions:

What did you do for a living before you retired? You mentioned having a lot of other “back-to-basics” skills…?

Having learned various aspects of cooking and baking, from my grandparents (some direct, some through my parents); I decided to explore some of the other aspects of “just plain living” exemplified by my ancestors. I was – no – am an Eagle scout, And all that goes with that.

My Dad had taught me wood working and various “seat of the pants” engineering and home maintenance – both parents were skilled in the culinary arts. I grew up a “natural artist” and craftsman. I studied both Engineering and Art at the University of Pittsburgh

I worked for 34 years for the US Dept. of Labor, Mine Safety and Health Administration (MSHA), Approval and Certification Center (A&CC) which evaluated and approved equipment for underground mining.

For the last 29 years of that career, I ran the explosion-proof testing laboratory which evaluated the individual pieces of equipment (i.e. boxes/enclosures) as to the ability to contain and prevent the propagation and occurrence of situations that could lead to a mine explosion. I had to design tests, at times, and even make my own “specialized” tools; understand plumbing/gas/and a ton of other skills. My German grandfather had been a highly respected Master Plumber, which helped.

I retired at age 55, at the end of 2010.

I taught myself some of the things my grandparents did, but that my parents had not passed on; including making butter, yogurt and cheese (being Irish, on one side, wine/beer making came naturally). My Lakota (Sioux) side had a natural affinity with the Boy Scout/survival/plain(s) living; just plain common sense, among other skills.

What are you using for a equipment?

Feeling a little crafty today (and since it came up to 60F, outside); I went out to my shop, and cranked out a Dutch style cheese press.

Here are a couple of pix of home made molds. The wooden ones impress a Teddy bear and the word Bear. The PVC ones are for basic brick-shaped cheese.

I found a dual-read Temp and RH meter at Lowes for $20 that is fairly accurate. Nice because the distant sensor is small and doesn’t take up much space.

I just waxed and put away a small Havarti, still have a Swiss and 2 Pepper Swisses aging at 71F. and a Farmhouse Cheddar air-drying.

The next two Pepper Swisses go in tomorrow and I just started a 4 lb wheel of Swiss. The first of a weekly production cycle for the next few months in prep for farmer’s markets.

My wife does pot pies and I do artisan breads and pickles, too.

Me: Is it legal in PA to sell your cheeses at Farmer’s Markets?

Yeah… it requires a $180 license for the year for meats and dairy goods. It’s actually cheaper to get a “cottage industry” type license, but the health inspection is almost as tight as for an institution.

PA may require a food handlers license, but the wife and I both have them, as she’s 2nd chef at an institution, and I maintain a lower level certification.

Meanwhile, I have 2 cafeteria food service cabinets, which I am retrofitting to be cheese caves – one for the garage (45-50F) and one for my root cellar (55-65F). Between the two, they could handle 500 lbs. of cheese, fully loaded.

Me: Can you get that much milk?

I’m calling a local dairy to see what can be worked out… maybe start with 20 or 30 gallon/week.

Later:

I’m in the process of building a small (twelve 4 lb. wheel capacity) cheese cave, just for the warm phase of Swiss. My coolers are becoming crowded.

Attached are photos of my back yard shed and deck work areas ; and kennel/dog zone (from summer). It currently has a nice 4” layer of snow in the yard while the Easter Island Moai looks on…

My cave (the new one I’m building (71F), will be in our dining room (we actually dine in the family room). Finishing up the door tomorrow.

The other two that will be made over the next few weeks, from cafeteria cabinets…one will be in my fruit cellar (50F) and one in the basement (60F).

This is the cave I just finished up…it is strictly for swiss during the warm phase… It can hold up to 12 of these wheels.

Me: The shelves look like they have slats in them- did you make those as well?

Steve: 3 interconnected slats, wire rack and mat. The 3 photos should explain it.

Broke into the Farmhouse Cheddar, that I put up to age a couple of months ago… Pretty tasty, nice mild white cheddar. Good thing, ’cause it’s on my schedule to produce 48 lbs of it later this month!

Research

As I mentioned previously, Steve shared a lot of information with me about controlling the temperature and humidity in his coolers. These are excerpts from his e-mails, complete with diagrams he made himself:

|

| The head of the thermometer can be seen on the lid at left |

Me: In the picture you sent us, I noticed that you stuck your thermometer in the top of your cooler…

Steve: I get those white coolers, all the time, from Omaha Steaks, and thought it was a waste to throw them away.

As an extra step… trays of ice cubes or warm water can be added to the cooler to get the initial temp started, and to cool down the inside, or even to tweak the temperature when opening to wash rinds, etc. My experience (aside from cheese) is that some of these coolers can hold a fairly stable temp, for days. I’ve thought about experimenting with one of the electric Heater/Cooler type units too, it would require a styrofoam cover over the air port, along with periodic monitoring…or an external thermostat…. Lots more experiments ahead!

I have an idea to make them even more versatile by running some internal tubing and a retainer reservoir, that can hook up to the kitchen faucet. Using the thermometer and adjusting for cooler or warmer…a few minutes of water running could achieve the desired temp and depending on frequency of accessing the cheese, could be very economical. The internal reservoir would act as a thermal mass to stabilize and maintain temp for extended times.

Here is just a rough schematic of the idea, as well as a ref concerning natural cooling, as used in underdeveloped countries. If I build one I’ll send photos as well as test results. I’m guessing the additions to a cooler could be made for about $30.

Me: Do you have to keep the cooler next to your kitchen faucet?

Steve: It could probably be a slip-on connection when needed, although proximity would be convenient; any hot/cold water source could also be used (laundry room,

etc). This is just the beginnings of some ideas I had this morning, and kinks and details would need to be worked out of course. But after 30+ years of running a government lab…I am an experimenter at heart.

I imagine, too, that a hand filled funnel system could also be employed…in any suitable location.

Me: If you want a challenge – figure out how to control (not just measure) the humidity in a wine cooler. If someone could figure that out, I think there would be a large market. I think that’s the #1 problem for home cheese makers.

Steve: True, very true…now in my experimental “to do list”…

Offhand, water almost always enters air, the larger the surface area of water the quicker the exchange. So a simple solution of just getting water into the air (more efficiently than a wet napkin, at least) would be as in the illustration attached. Control could be by way of water quality – salty water … slower, purer water, faster. Not many studies have been done with this as far as I see. Here is a link to a report of one study (not particular to cooling a wine fridge, just generic): http://www.waderllc.com/Finley/Evap_Paper.pdf

Me: So, if you made something like that and put it in a cooler, you could measure the humidity over time with a hygrometer to see how well it was working?

Steve: …that’s my theory, at least. So far, I’ve got by, using a mesh plastic mat (open enough to not hold liquid) on a wire rack with 1” airspace underneath, then an upside down bowl over top, with a few inches breathing room. But making more and larger cheeses requires a larger “cave.”

I’m sure any of these low tech designs would have to be evaluated in each circumstance used, of course. But, it should be able to be determined with relative ease for the specific application. Also, just using a styro-cooler with the cheese thrown in with a cool or warm thermal mass is less effective than, say, pre-warming/cooling the cave…so temperature interchange to the walls is minimized. Hence, running tubing around inside and making sure you run enough water to bring the walls into accord with the expected temp.

Once it goes over $60, a wine cooler/fridge becomes more economical. Looks like I have my winter’s worth of experimental research lined up.

Later:

While I’m running some experiments on controlling temp in a styrofoam cooler, there is plenty of time for research, between measurements.

One thing I ran across, concerning humidity, is the following:

One way to measure hygrometer accuracy (or to help calibrate accuracy) is the “Salt Test.” The Salt Test is fairly accurate, but not appropriate for the most demanding applications:

Take a ziplock bag and place your hygrometer(s) into the bag, face up. Then, you will take a bottle cap (plastic 2 liter cap works well) and pour some standard table salt into the cap. Next, you will add a small amount of distilled water, until the salt is the consistency of slushy snow. Close the bag very tightly. After twelve hours, it should read 75%.

What this also tells me … scaling somewhat up to the size of my cheese cave, is that taking about a cup of table salt and adding water to make the slurry, should yield about 75% humidity in my cheese cave. I have a hygrometer on order and will check this idea out, once it arrives…

Later:

I found additional info, which I am passing on immediately as this is apparently standard available info, and of great import to the home cheese-maker. (This is the second document when you click here). I am running tests on this anyway…

Later:

Although I am not finished with the experiments, let me share with you the “trends” that I am seeing.

Temp tests were conducted without regard to humidity (though house ambient was about 50%), and 71F (very stable) in house.

Humidity tests, so far, have been conducted without regard to temp and without thermal mass, etc., though, again, house temp was 71; as was the cooler, whenever I checked it.

As to temp, a large thermal mass can control the temp for quite a bit of time. I’m talking basically a mass of water equal or greater than 15% of the cooler volume.

And, of course, in all cases the measurements vary somewhat depending on location within the cooler. I’m trying to normalize by measuring in or near center. I have more to do here, with ice packs, greater volumes, etc.

Humidity – The saturated salt solution is yielding a 75% humidity directly above and close to the source, going as low as 60% in the bottom corners, bur fairly normalized at 65% in most of the cooler.

Adding a cup of water boosts it up another 5% reaching 70%; and adding the wet paper towel “radiator” boosted it to 75% within a very short time.

AND since I started writing this update…has already climbed to 82%.!!!

Now all I have to do is find a “balance” point and go from there, then combine temp and humidity and see if I can get it ALL under control. Later:

Had some very good results today. Using the cup of saturated salt and the small bowl of water; I was able to maintain, without attendance, an RH of 80% at 71F for four hours, very stable.

Removing the salt lowered the RH to down around 74% within the hour. Adding the salt solution back in resulted in a rise back up to 80% RH.

As I mentioned earlier, the paper towel “radiator” really sped up humidity rise. I find, also that the size of the radiator plays a significant role in the speed of humidity

development. Thus, this shows repeatability, and several items of control that can be added, removed, and adjusted to yield RH ranging from 65% to 85%, at least in the short term (ie. daily).

Later:

BTW…attached is a photo that I meant to send with the last email. I’m using a sheet of acrylic as lid.

Me: When you had the RH of 80% for 4 hours, does that mean it was only for 4 hours or will it last longer?

Steve: Had it for 4 hours…Then after removing the salt solution for 2 hours, I put it back in…RH went back to 80 and has been stable since. That was just under 7 hours ago… so, 11 hours total, not including the “break!”

This was at 71F, now have to work the combo of temp at 55F and RH at 80%, and whatever adjustments that may require…

Later:

So here it is, 8:30 am the next day and still 80%.

I even simulated going into the “cave,” removing cheese, then a few minutes later; going back into the “cave” to replace the cheese…in an hour and 1/2 it was again, back up to 80% RH! So far, that is about 19 hours.

Meanwhile, I set up a small scale experiment (see pics) in my 42F crisper of the fridge. It will take 12 hours for the salt to stabilize to it’s equilibrium, but initial observations seem to indicate that there is very little effect from the temperature….I’ll know for sure this evening.

Me: Your crisper is 55F? Is that sealed or will you have to get the whole fridge to 80% humidity?

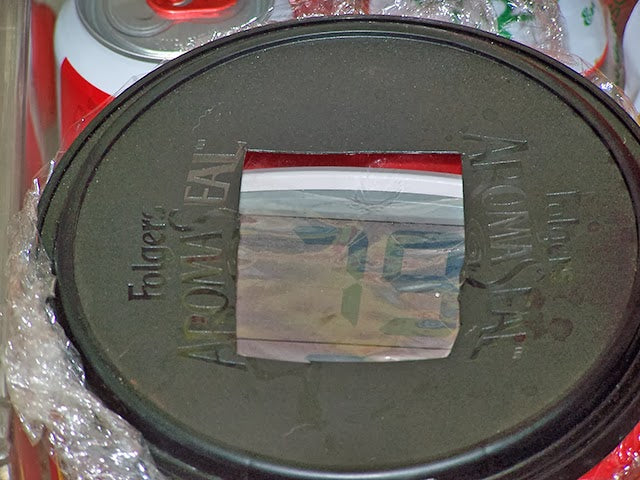

Steve: My crisper is not air tight, but I’m running the experiment in an airtight coffee can (to simulate a Tupperware cheese cave.) The crisper ranges between 35 and 42F, depending on fridge usage. I’m not doing this one for a specific temp, rather to show that the water and salt sources are mostly independent of temperature, which so far (3 hours in) seems to be the case. I will get back to temperature work on my Omaha Steaks cave in a day or two.

Later:

From what I’m seeing, the quantities of salt and water, do not seem to matter as to final RH, only affecting the time it takes to get there. Temperature seems to not be making a difference (so far).

Thus, a small Tupperware cheese cave only needs a small amount of each to reach 80%RH in, say, an hour/ hour and a half. While a larger cheese cave (cooler size) would need a larger amount of each ONLY to get there in the same time frame.

All this providing that the saturated salt and the water containers have approximately equal top exposed surface areas, and more than enough water to get humidity into the air.

I suggest for a small cave- a tablespoon of salt with about a teaspoon of water mixed in…it needs to be like slushy snow consistency. The water should be about an equal volume (not really critical) and the same sized

container.

For a cooler sized cave… scale it up to 1/4 cup of salt with a tablespoon of water and a corresponding sized water container.

Saturated salts can take up to 12 hours to stabilize their own gas vapor/liquid balance (for calibration purposes at least), but so far I haven’t seen any difference on the cheese

caves. As we are not calibrating here, it really doesn’t matter if the salt balance is 75.1% or 75.6%.

So, in short, an adequate volume of water and saturated salt solutions, both having about the same exposed top surface, seems to always stabilize at 80%. This makes for a handy “rule of thumb” not requiring direct measurements.

I’m running a week long RH on the cooler. My guess is that as long as there is some water, and the salt hasn’t dried out…it’ll keep going. Otherwise, a periodic water addition to either might be needed. My salt solution has been going for a few days so far and looks fine.

Adding the radiator gets a lot more moisture into the air and thus seems that it could be sized to control for higher RH (I’ve tried 2 sizes so far), but haven’t gone deeply there, yet; as 80% was my goal.

Attached is a photo of the coffee can in the crisper. Temperature is 37F, but RH is still 79% after a few hours.

Later:

My test in the crisper is showing 36F…and now that the salt should be stabilized…its showing 71%RH, so it IS temperature dependent; though not as much as I would have guessed, before starting all this.

I would THINK that at 55F the RH may come out around 75 or 76%, but I haven’t tried that yet. More to come…

Later:

…Now its up to 75% at 37 degrees…Guess I’ll wait for full stabilizing and check it before bed tonight.

I adjusted the fridge to be a few degrees warmer…the controls must have gotten bumped, because the temps I’m getting in there are 5 degrees lower than last week.

It comes to mind that when one is not using the Saturated Salt solution; it should be covered, capped or sealed. This will make it easier for next use. It then may be able to be used with just a quick stir and any additional water that may have been lost. This is typical of what is done when using it as a calibration source.

Later:

Well, everything has stabilized in my coffee can cave in the crisper. Temp is 40F and RH is 75%. This would indicate that RH at 55F should be 77-78%. I’ll do a few more readings between now and tomorrow and confirm stability.

Meanwhile, the larger Omaha Steak cave is still at 71F and 80% RH, very stable.

Later:

Both the Omaha Steak cave and the coffee can cave are stable: Omaha on day 4 still 71F, 80% RH. Coffee Can Day 2 still 42F, 76% RH (stable since last night).

I will let the coffee can run for a few more days, but then I need the fridge space. I will allow the Omaha to continue for at least a week, probably longer. If I can get a setup at 55F, at some point, I’ll let you know. I’m willing to bet it would be 78%

Me: How will we know how long the salt-water combo is good (beyond a week)? Some cheeses need high humidity for a couple of months.

Steve: As long as there is liquid in the water source and the salt source, it should be stable.

I plan on leaving a test run for a month, or even longer.

I also have a set up with a cheese cave inside a cooler…the cooler being cooled by a 1 gallon block of ice. Over the past 30 hours, the cooler has only risen 2 degrees (to 54F). I’ll let you know more on that as I obtain more data.

Additionally…

To keep around that 80% range you do not want to add more water to the air from accidental splashing,

spritzing, etc…that will drive the humidity higher.

Of course, you may want higher humidity…but best practice would be to use some type of “radiator.” By controlling the surface area of the radiator, you limit the water getting into the air. I have not, as yet, determined rates, sizes, etc for that type of arrangement…maybe a future set of tests.

Later:

Here’s is a portion of what I’ve written up so far…

An easy “no frills” low-tech solution for temperature and humidity control while aging cheeses.

Making a saturated salt solution consisting of 1 tablespoon of table salt and approximately one teaspoon of water, and mixing until a “slushy snow” consistency; yields a stable humidity controller when used in conjunction with an equal amount of water. One acts as a humidity source while one acts to regulate the humidity. The salt solution takes an initial 12 hours to stabilize. This solution, in a closed sandwich bag along with a hygrometer may be used in calibrating the hygrometer. The solution will yield a stable 75% RH in such a small environment.

After 5 days of extensive testing the following was determined:

Placing this salt solution and a water source inside a small cheese cave that fits in a crisper will yield a stable 78% RH at 55 degrees. The range will vary somewhat based on temperature.

Results:

Measured Values were:

TEMP RH

38 F 67%

42F 73%

50F 78%

71F 80%

An 11 gallon cooler was also used, the salt solution was scaled up to ¼ cup salt with about a tablespoon of water and a corresponding sized cup of water. A stable 80% RH was maintained for 5 days at 71F.

For those thinking, “Oh heck, I just use a crumpled up, damp paper towel, and I do fine.” I would point out that due to the variability of exactly how you crumple your paper towel and lay it in your cheese cave; you may end up with RH anywhere between 40 and 90+ %. The above, however, gives a fairly precise method, with minimal fuss or monitoring.

Later:

This arrangement was set up and now has been going on for 30 hours. It has maintained the cooler at 52 to 55F.

Meanwhile, the sealed “cheese cave” (a plastic coffee can) inside the cooler, having the salt solution, has maintained at 53F with 75% RH during this time frame.

This would be a scenario, that I myself would likely use, as it would be a system that needs the ice to be replaced every few days, and requires no electricity and would be small enough to put away when not in use.

As a rule of thumb… I would say in scaling the salt solution and water source to the cave:

For every cubic foot of “cave” … 1/8 cup salt with 1 to 1-1/2 teaspoons of water for the salt solution; and 1/8 cup water as source. Equal top surface areas, and somewhat symmetrical (ie. 1” deep, then 1” diameter approximate.)

Actual amounts do not seem to be critical as long as there is enough water to go into the air, but I would use this as a base line, since it worked so well in the experiments.

Personally, on the science side…I wasn’t on the chemical side of science, so can’t “professionally” say what all the interactions are here.

My best guess is that the water will attempt to put as much water vapor into the air at a rate that it can with its available exposed surface area.

The salt continues to try to achieve a 80% RH by drawing moisture out of the air and releasing it back in an effort to reach its own equilibrium. Thus it will try to get to 80%, though actual temperature of the cave may condense moisture out.

Since the cave is sealed, there is no water loss; merely redistribution. The redistribution to walls, floor. ceiling of cave then assist to raise humidity too, because of large surface area.

RH can also be increased through the use of a dampened paper towel or cloth having a wick resting in the water. Most efficiently, this would occur if there is maximum air around the cloth.

I haven’t fully studied that aspect yet…but initial observations (using a single paper towel sheet and later, a 1/4 sheet strip) indicated that size functions as a control to amount of increase.

I’m running a test on my own cooler (fortunately I have 4 of them).

Adding a 1 gallon jug of ice into the cooler, with salt and water sources, generally only gets to 65%RH. This is due to the ice mass condensing so much water vapor on its surfaces.

Removing the water and salt solutions from the cooler and putting a cheese cave into the cooler, the cave having the salt and water solutions is similar to putting the cheese cave into the fridge. The cave environment is separated from the fridge environment. The cooler goes into the 50Fs with low humidity while the cave sits in the 50Fs with 75 to 76% RH, not quite 80, but close…and predictable.

Later:

My latest 2 lb Baby Swiss in a Tupperware container. 2nd stage (warm) of aging. 86% RH, 71F…using the saturated salt and water source.

And, inspired by a daughter…a Pepper Swiss brick in the mold.

Me: They look great! How are your cheeses coming out (tasting)?

Steve: So far really good, I’ve only had two I wasn’t happy with, one a Colby; I got it into a hard cheese stage instead of a semi hard (but it still tasted good); and a sage derby where I used dried rather than fresh sage, which tasted a bit “musty.”

I’ve done all of the cottage types from vinegar; and cream cheeses, spreads, whizzes and velveeta-like. Some near cheddars, mozzarellas, etc. Latest was a mild pepper jack, the current swiss and pepper swiss. I’ve made fresh yogurt (regular and Greek style), and butter.

I usually make my own meso- (buttermilk) and thermophylic (Dannon) cultures, and have used both tablet and liquid rennets.

My nephew just loves the spreadable cheeses from vinegar (there’s cream in the mix, too) (like my Bear Whiz, Beer Whiz and Fire Whiz)

Being a craftsman, woodworker…I’ve made some of my own molds; one of the latest I used on my mild pepper jack (impressed with the Bear seal…).

Later:

As I end the day…using my salt regulated humidity techniques…

An older Swiss, in second (warm) stage 72F, 90% RH, in Tupperware cave, and two new “pepper swiss” in stage 1, 60F, 65% RH in cooler, with small ice pack. The older smells so wonderfully swiss, that I can’t wait for another few months!

Later:

All of my testing was based on an empty cooler (to minimize variables); now that I’m using the salt RH control… I’m finding that the cheeses just going (young cheeses) are raising the RH to 90 – likely due to the cheeses “sweating” out extra humidity.

Later:

Just an FYI on observed results now that I have a few Swiss cheeses in caves at multiple stages. Cheeses in cold aging are maintaining at 50F with 85% RH, warm stage steady at 70F 85% RH (briefly peaked about 93%).

When I open the caves to flip, dry or brine… everything comes back stable in just a few minutes (and the warm stage swiss smells so good…I just want to eat it now…or move into the cave!).

Based on all of these results and a few trials with cooling the large styrofoam cooler, I’m designing and likely build a cheese cave using styrofoam (Omaha) coolers.

It’ll have an ice section for ice packs and/or gallon jugs of ice, that are separated from the aging section, and possibly with a vent/window for slight adjustments. I’ll photo-document if I do it.

Later:

So, since the last time I wrote…

Exposed cheese seems to assist, at times, with the humidity; and I have even removed the salt and/or water, at times, once the preferred RH level was achieved.

I have been maintaining a 71F, 79% RH for my Swiss, with virtually no attendance required. Lower temps (50 to 60F) seem, for me, to be stable with 75 to 77% RH.

(The photo shows 2 of my “cooler” caves…the sealed one has my Swisses, as you can see at 71F, 78% RH.) (this has been maintained, stable for a month).