Cheese Making Recipe of the Month

SALTING YOUR CHEESE WITH BRINE

Brining seems to be a simple matter of adding salt to water and letting the cheese absorb it's salt for a while, but there is more to it than that!

- How much salt?

- How long do we leave it in?

- How do we replenish the salt?

- How long can we keep our brine?

- What do we need to do care for the brine? and lots more

Cheese Making Questions & Answers

Raw Milk? Cheese is Developing Cracks? Mozzarella Too Firm?

Q. I was wondering, is the cheese still considered 'raw' after being heated to 102F degrees?

A. Are the components of raw milk still viable at this temp? Yes, most of the enzymes and nutrients as well as the bacteria in raw milk have a fairly active life between 65 and 102F any cooler and they slow down, warmer and they begin to be damaged and die. Think about the fact that our body temperature is normally 98.6 and the cow or goat's is very close to that.

Q. My question has to do with the cheese during the drying stage. As the outer surface is drying it develops large cracks. I am using the recipes from the cheese making kit. I also purchased Ricki's book which has been very helpful regarding other items. On my first go with Farmers cheese and using liquid skim milk (plus cream) all came out fine during drying. The next two times of making both the Farmers and Colby cheeses, using powdered milk (plus cream) they are showing this cracking problem. The action looks like there is too much moisture in the wheel. I have been using a cheese press with the recommended weights. Do I need to add additional weights to extract more whey? I reside in Loveland Colorado where the humidity is in the 20 to 40 percent range. Would appreciate your comments on this.

A. Your problem is not the cheese inside being too moist but the air outside is too dry. During the winter the air humidity is nil, I pumped about 5 gallons of water a week into my cave when the temperatures here dropped too low. This is a common problem during the winter and you will need to find a more humid area for these cheeses 65-75% will work.

Also thinking about pressing for a drier cheese is not an option. The final moisture control needs to be done in the vat with the heating and stirring Your final cheese will have 2 types of moisture, water bound in the curd this is not going to be released by press and water that is free and can be removed by pressing. Pressing is for consolidation of the curd and release of final moisture

Q. I made Mozzarella for the first time this weekend. The results were pretty good, for the first attempt. We made pizza with it and it tasted quite good. I will say that the texture was not quite what I had expected, though. It had a firmer, drier texture than what I am more familiar with for fresh Mozzarella. It was a bit more like Brie than it was like Mozzarella. It also didn't melt anywhere near what I am used to for fresh Mozz.

A. Brian it sounds like your process went ok as in all cheesemaking, you will find it as much an art as a craft, very different from following a recipe for cookies. During the process you will find many points where you will have an opportunity to change the outcome of your cheese cheese, in this case you produced a fairly dry firm mozz with less moisture than the fresher versions. In order to produce the soft squishy mozzarella that you are looking for, keep the initial heat a little lower (our instructions mention adding rennet at 90F and heating as high as 100-105F). By keeping this initial heat in the 90-97F range you will keep more moisture in the curd. You can also knead it for a shorter time thus not driving off as much moisture and after heating in the microwave limit the amount of stretching you do.

Have a cheese making question, we're here for you: info@cheesemaking.com

Whats New at Cheesemaking.com

Jim, the tech guy has just returned from a fabulous 4 day workshop at U.Vermont's Artisan Cheese Institute focusing on 3 Alpine style cheeses. The workshop was conducted by 2 experts from the french cheese school 'INRA' in Poligny France, Dr. Eric Beuvier and Gabriel Duboz as well as several of UVM's Artisinal Cheese staff. We also were enlightened by a visit and presentation from Sister Noella (the Cheese Nun) who as it turned out had Dr. Beuvier as her doctoral thesis mentor.

There was little left to the imagination as we explored the similarities and differences of Comte, Abondance, and Morbier cheese. Jim will include more on this session in upcoming News Letters.

News From Fellow Cheese Makers

Cheddar Cheese Workshop

Jim, I want to thank you again for a most wonderful and educational workshop last weekend. As promised, I have put together a short Power Point presentation of photos from the cheddar making session. It can be downloaded Here

Making Cheese and Loving It!

Hello Cheese folks!

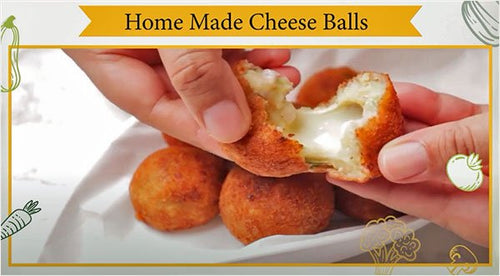

I just have to tell you how excited i am about making cheese. I ordered the starter special it's great. Yesterday morning when I left the barn I snagged a gallon of fresh milk off the line from the milking parlor (we milk 400 jerseys and grow all of our food), made a batch of 30 minute mozzarella super easy directions, used some of the whey for pizza dough and fed the rest to the pigs they loved it and had pizza with fresh mozzarella, pesto ,roasted garlic and onions for dinner, oh my god, what it going to happen to me now. This morning I made another batch of mozzarella and rolled it in fresh chopped sweet Italian flat leaf parsley that is still growing in the garden, will make the Italian Feather Bread to go with tonight's dinner, tomorrow I will try the fromage blanc and then make queso blanco for our Hispanic employees. I will be ordering cultures next to start making other cheeses. Good thing we have lots of milk! I used to make cheese with my mom when I was a kid, but always remembered it as too much work, what was i thinking???

Now I have the reward of fresh cheese and a glass of wine every day when barn chores are done! Life is good.

And just how long will that rennet last!!

My mom recently gave me a cheese making kit she purchased from you guys but never had time to use. She told me it must be 20 years old (but the catalog in the box had your URL so it can't be quite that old) Anyway, The kit included the tablets of rennet, I tested one and it seemed to work on a small scale so I tried a larger batch! One tablet gave me a nice curd in 1 gallon of milk! The curd is being pressed right now (I'm trying farmhouse cheddar) and I'm excited to see how the cheese comes out!! I wanted to let you guys know that the ancient rennet seems to be working well! Thanks for having such great stuff available!

Another Customers cheese press idea

I thought I would share some photos of a cheese press I made today using a laminated board, threaded rod, a piece of angle iron and a 1inch dowel. I have to admit, I did have a piece of 3/4 inch plywood and some Formica laminate hanging around my garage but this is pretty rudimentary and takes good advantage of simple leverage. The red marks on the iron are 6inches apart so a 5pound weight at six inches from the follower is 5pounds, at 12 inches away it is 10pounds of pressure.

A letter from Africa

Dear Ricki,

I have just come back from Africa and we had a great time making cheese, yogurt, ice cream and butter. The people there have asked me to send their thanks for the donation of cheese making supplies. It was greatly appreciated.

Please send your cheese making news & photos to: moosletter@cheesemaking.com