Cheese Making Recipe of the Month

Cheese Curds. Yes, those cheese curds ... squeaky little cheese snacks!

Well ... I have had so many requests for this recipe I finally had to find time to develop a good recipe for those that wanted this one. I guess this would fall into the comfort food category! .... defintely a fun cheesemaking adventure for the family!

Cheese Making Questions & Answers

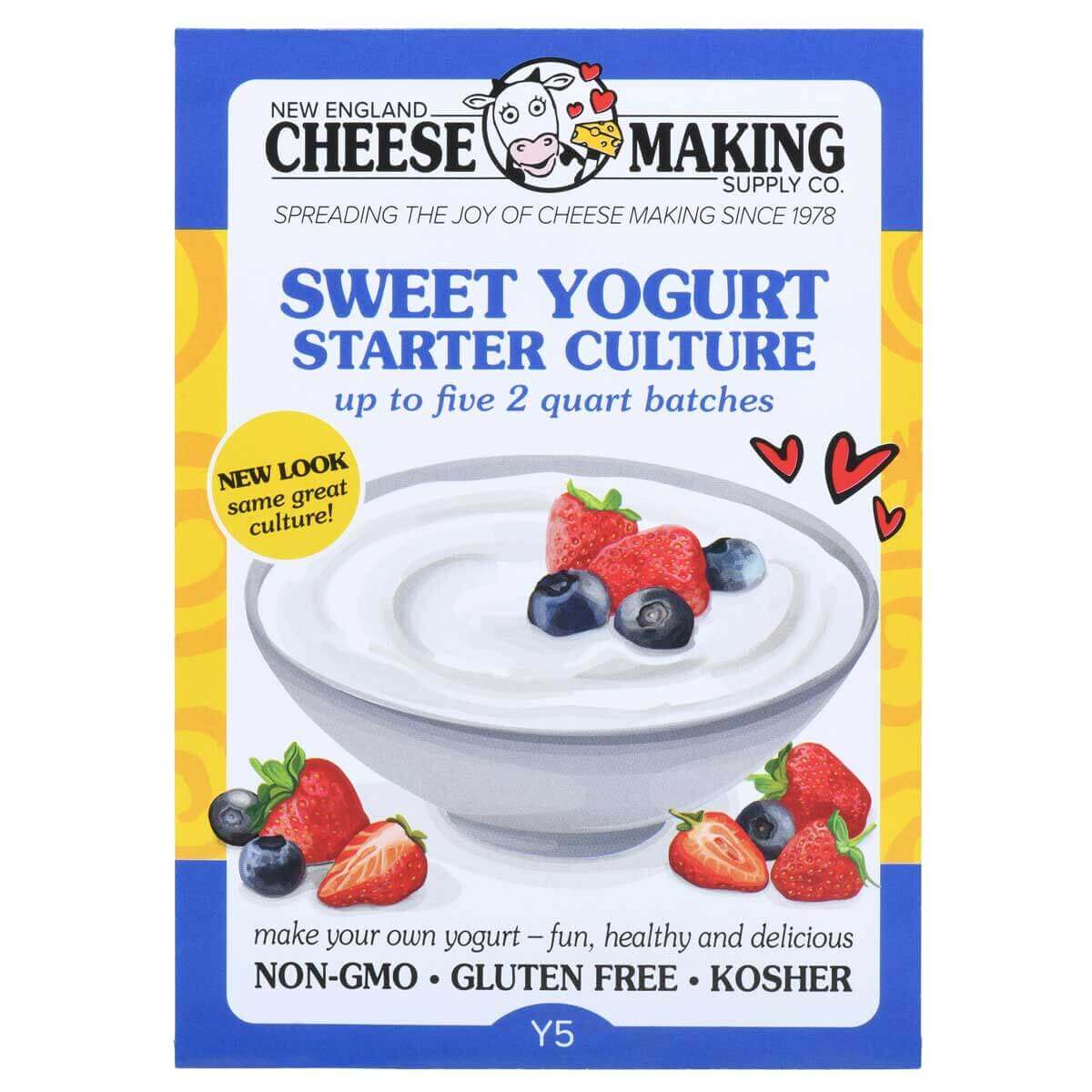

Q ... My yogurt never seems to become firm enough. I use raw whole milk and only warm it to 80 degrees then add culture (Y5), bottle in quart jars, and place them in a warm cooler for 36 to 48 hours.

A... I do hear from many people who would like to make yogurt from raw milk and still preserve the natural flora by only mildly heating the yogurt ... This is not the original yogurt process as it originated or currently practiced at it's source in eastern europe .... The milk should be heated to 185 and held for 10-20 min to take advantage of the whey proteins ... these are what help make a firm yogurt .. then cooled to the target temp of 108-112F and inoculated with a thermophilic yogurt culture

Also 80F is on the VERY low side of where these types of cultures work (optimum is 108-112F) .. why not preserve the natural cultures of the milk by making fresh cheese at lower rtemps and take advantage of the yogurt benefits as they were originally practiced???

Q... I was wondering, is the cheese still considered 'raw' after being heated to 102 degrees

A...Yes ... most of the enzymes and nutrients as well as the bacteria in raw milk have a fairly active life between 65 and 102F ... any cooler and they slow down ... any warmer and they begin to be damaged ... think about the fact that our body temp is normally 98.6 and the cow or goat's is very close to that...

Q... How does acidity effect the flavor and texture of your cheese? How do I find the "normal acidity levels " to use as a starting point for certain cheeses? Are certain cheeses more sensitive to acid levels - you have to be "closer" in order to get the desired result. Can I increase the amount of starter added to "adjust" the flavor of my cheese? will this effect acidity?

A... Flavor and texture are a result of the type/amount of culture you use, the quality of milk, and the process timeline in your cheese making but equally important is aging conditions..

acidity as pH or TA% is one part of the make program for each cheese .. too much or too little acid will alter the curds ability to retain calcium and hence the final texture ... also the rate at which acid is produced plays a big role in the final texture of the cheese and the way in which it ripens ... The best book that really lists these factors is Paul Kindstedt's 'Artisan Cheesemaking ' and goes into this in detail ...

Essentially if you do not develop the proper amount of acid in a specific time then the cheese you make will be different than what you planned on making ...

... Of course at this point we have entered the realm of advanced cheesemaking ... much more than can be dealt w/ in an entry level book such as Ricki's which is intended for home cheesemakers... this is the type of material that I teach extensively in my cheesemaking 201 courses (actually a cluster of courses dealing w/ very specific cheeses)

The amount of acid in your cheese will alter not only the flavor profile but the moisture content, texture and it's ability to ripen properly in it's proper timeframe

Have a cheese making question, we're here for you: info@cheesemaking.com

News From Fellow Cheese Makers

Making a very basic cheese press that works!

I have made up a short description of the construction of my homemade Cheese press

Here is a picture of the final modification and advice.

Just so you know, I own my own machine shop and all the welding equipment you would ever want and have made my own metal castings too.

However, I chose to make a simple press that most anyone could make.

Metal racks for draining purposes become extremely slippery when wetted with water and butterfat curd fluids, so it is best to use a cheese mat under the mold or perhaps a wash rag could work too.

Most people can saw off a board and drive a screw and find some old boards and even some old hinges from discarded items in theirs or the neighbors scrap heap.

Many people don't have the skills required to drill accurate holes.

A bucket with a bail will do for weight if an empty gallon plastic jug can't be found.

A used bathroom scale can be found in a second hand store for just a few dollars or in your own bathroom.

I made my press out of two 2"x10" boards from the base of an old water bed that the neighbors threw away and a scrap 2"x4" for a weighted lever arm, but a wider board might work better for the arm.

The diagonal brace is a piece of 1"x2" pine as are the end stops for it.

The scale of the entire press does not matter so long as it works for you.

Just make up an assortment of lengths for push sticks with an assortment of wooden shims, and a board for the mold follower that will give uniform pressure so as not to distort it.

The lever arm on the one shown is marked off in inches to give you an idea of the size of the press.

The Cheese being pressed in the attached picture is a 5 1/4 pound Cheddar with 40 pounds of weight.

Just get the whole thing set up and set the mold with an cookie sheet under it and the curd in it and set the scale to zero "0".

It would be a good idea to shim up one end of the table or the press so as to make the fluid run away from the mold also.

Everything added after that is weight and will show on the scale as pressing weight, so just add the desired weight at the desired location on the beam and start pressing.

Some attention must be paid to getting the push stick correctly located so as to keep the mold follower from tipping one way or the other.

The press folds down for storage and if you want it to be even smaller, Just grind or saw the end of the hinge pin on the lever beam and drive it out with a punch, then file down the pin for a nice slip fit or just replace it with a slightly smaller diameter, Large Nail!

From: Butterfly

Buffalo Mozzarella

Good morning Jim,

Months have passed since I received your advice on how to make buffalo mozzarella in the microwave. (You may recall that I am currently living in Brazil and have access to buffalo milk.) Your advice seemed to work!! Yeah!! I'm not sure what part, but today (the first time I've tried to make it since receiving your advice) it worked. For your information and for future use, this is the recipe I used:

- 4 liters of water buffalo milk

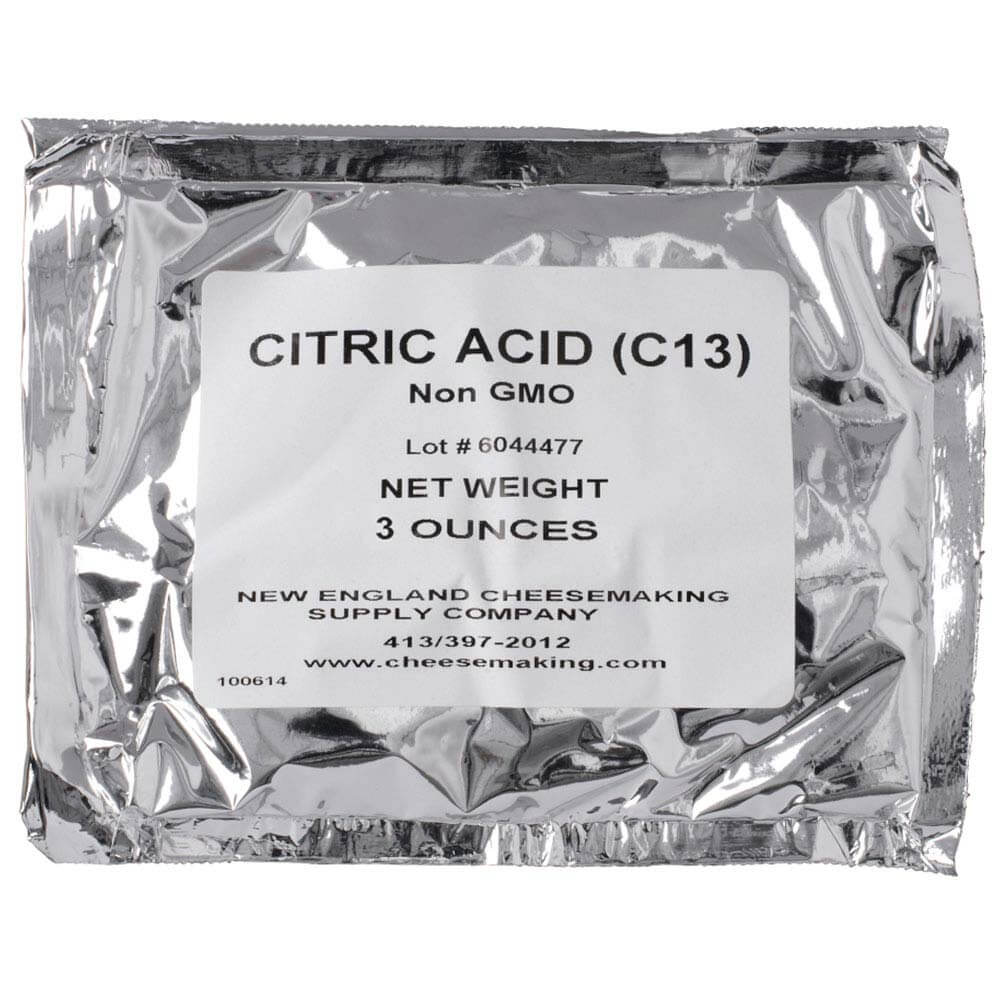

- 3 1/2 teaspoons citric acid

- 1/8 teaspoon liquid rennet

However, I think the most accurate part of your advice was to increase the temperature. I didn't pay too much attention to temperature readings but when the curds came together in the pan, I removed them. Also, I microwaved the cheese for a minute and a half during each session. It worked!

I do have one more question. Why is it that the appearance of the cheese changes as it cools. It seems to take on a greenish-grey hue on the parts exposed to the air. Nothing too drastic or ugly, but certainly not that beautiful white mass that I start with. The taste remains uneffected <JW!... this is the curd reacting w/ oxygen in cows milk I see a darkening or deeper yellow effect>.

Thanks for your help, and I will try to send some photos of the buffalo, the farm, and the cheese making process.

Sincerely,

Scott Matzen

Himalyan Cheese Making

From: Joy Schulenburg

Rewalsar, H.P., India

Thanks! This stuff all has to get shipped together via my daughter to my home here in the Indian Himalayas (near the Tibetan border -we work with mountain tribes and Tibetan refugees up here) so having things all show up at the same time is important.

And it would be dumb to run out of rennet - there is absolutely no way to obtain any up here without going the kid's stomach routine and, because most folks are Buddhist, we don't eat kids, only older animals so that would be really tricky!

Where I am at, EVERYTHING is local and homemade. In fact, people have very strong beliefs about local and homemade. We get warned not to drink too much of the milk that is sent up here in boxes (and is ultrapasturized to stay sterile on the shelf) because it is "dead" - which of course it is. But the same is true of everything here - veggies as well. If it came from more than 30 kilometers away, it is probably "dead" by the time you eat it. The local wisdom is that 5 km is optimal.

So where we get our milk? Usually it's from our landlord's cow who lives on the other side of the road. She gets all of our vegetable peelings, fruit rinds and peels and other organic scraps to eat and, in return, gives us wonderful rich milk. Some of it goes into our coffee and tea, but most of it becomes homemade yoghurt and paneer and the whey from the paneer goes into the bread I bake from wheat harvested in the next valley. Herbed yoghurt cheese is wonderful smeared on homemade bread!

We also, as the local emergency medics, get gifts of milk and cheese from our friends and patients. Nobody would ever think of showing up empty-handed and often what they have is milk - very frequently in a recycled soda or water bottle. The Tibetans, particularly the nuns and the monks who live in the caves at the top of our mountain, are as likely to turn up with either yoghurt or the very hard pellets of churra, the Tibetan travelers cheese.It keeps literally for centuries! The Tibetan's yoghurt is thicker and sweeter than the Indian villager's thin tart yoghurt here and I prefer to use it as starter. That's why I like to have a bunch of your starters to hand though - if I don't have any Tibetan style yoghurt or yoghurt that originated from yours - I'll use the powder to start a new generation. The Indians mostly use the thinner, tarter yoghurt for cooking and it's fine for sauces, but not as good for eating or making Tibetan food.

We have thousands of sheep and goats troop by our house each week en route to other pastures. I'm still trying to find a shepherd willing to sell me some milk - much of it is a language problem as they speak some dialect that is only a vague cousin to either Tibetan or Hindi which is spoken in the village. I'd really like to get some goat's milk and make Gjetost, my favourite cheese, as well as a good feta, another favourite. However, right now, I'm happy with what I am producing as better than the alternative which is no cheese whatsoever. A friend came by with 2 gallons of fresh buttermilk the other day so we now have a nice pot of buttermilk cheese (from your recipe!)

Whoops, this was supposed to be a thanks for trying and reply to your footer and it's turned into a cultural dissertation! Basically what I was trying to say is: Unfortunately, I don't think my cow across the road and the nuns up top are much of a source for your books as it's erratic and a little far <grin.>

Would you ever be interested in the recipe for Tibetan cheeses? Churra, for sure, is a hardened buttermilk cheese and there are a fresh cheese and a blue cheese as well which are way less common. I've made the churra once myself, but since others make it in huge batches, I rarely have a need – I get kilos as gifts at the holidays. There's also a Yak cheese (actually Dzo – Yak is the word for a bull) made even farther up in these mountains and in the mountains above Kathmandu, that's really nice – flavour that varies from something like a Gruyere to more like an long-aged Gouda, depending on the batch and the aging. I'm trying to find the recipe for that, but I hear it's made up in Ladakh and I plan to visit there next summer.

Thanks for all you do for us cheese-lovers. May you prosper and all your microorganisms be beneficent!

An Ode to the Cow and the Milk

Donella Meadows from The Global Citizen,

Years ago, when I went out to my new chicken house and found the very first freshly laid egg, I stared at it in awe. "How did that hen DO that?" I wondered. She takes in grain and bugs and kitchen scraps and turns them into an EGG! Shell on the outside, white and yolk on the inside, all proper and perfect. Under the right conditions (or hen) that egg could even become a CHICK! Just amazing!

I still think every egg is a miracle, though they appear on our farm by the dozen every day. Our leading-edge chemists are miles from being able to convert cracked corn and cabbage leaves into an egg, much less a chick. The biotech biz can't make grass into wool and lambs either, though my sheep, which were not at all smart, used to do it with great reliability.

All these years the one farm miracle I never got to witness firsthand was the transformation of hay into calves and milk. I never got a cow. I was daunted by their size and by the prospect of never-fail, twice-daily milkings. "The only difference between being in jail and having a cow," my then-husband used to recite, "is that in jail you don't have to milk the cow."

So I stuck with chickens and sheep, until two years ago, when one of my farm-mates drove in one day with a tiny Jersey calf in the back of the truck. We named her Maple. Maple has just had her own first calf, and we are awash in milk.

I shouldn't have been surprised at how GOOD fresh, sweet, organic milk is. After all, once I tasted fresh organic eggs I never went back to supermarket ones. The same goes for vegetables and fruits out of the garden. But somehow I thought milk was milk was milk. So I have just learned one more time what we give up in taste and quality for the dubious privilege of living far away from the sources of our increasingly industrialized food.

I was also surprised at the quantity. Jerseys are not big producers, and ours is still working up to her peak, but she's already milking five gallons a day. That's nothing to a big farm with Holsteins and vacuum lines and bulk tanks. But when you're operating out of your kitchen, five gallons a day is a river -- a river of possibilities. You can do so many great things with milk!

Most of ours goes into cheese. Up to a month ago I had only the vaguest idea how milk becomes cheese -- though this age-old art was once practiced in most rural households.Here's how it works. You heat milk gently in a stainless steel vat and stir in a magical lactobacillus that turns the milk sugar lactose into lactic acid. You monitor the acidity of the mix to follow the bugs' working. At just the right moment you add rennet, which congeals the curds. Then, depending on what kind of cheese you're making, you cut, heat, stir, salt the curds, scoop them into cheesecloth-lined forms and press them (with bricks or a bucket of water). The next morning you have a wheel of cheese. You soak it in brine, then age it, ideally in a cave with constant temperature and humidity. Lacking a cave, we built a walk-in cooler.

We just tasted our first cheese, now 45 days old. It's bland, because it's only halfway through its minimal aging period. But it's nutty, elastic, melty, good cheese. In my totally biased opinion, it's on its way to glory. As with that first egg, I'm in awe.

I am not good at delayed gratification, so I take some milk to experiment with products that can be eaten immediately. So far my favorite trick is this. I start with two gallons of milk and scoop off the top layer of wonderful, thick cream. The cream goes into a hand-cranked churn. After 20 minutes of lackadaisical cranking (I read a book while I do it), the paddles hang up on a half pound of golden butter. I pour off three cups of surrounding liquid, which, kids, is called buttermilk. Great for biscuits or pancakes.

Taking off the cream leaves a gallon and a half of skim milk. That I warm to 90 degrees and stir in a little commercial buttermilk (which contains live lactobacillus). After sitting overnight, it separates into white jelly-like curds and watery yellow whey. (Along came a spider and sat down beside her ... now I know where those nursery rhymes come from.) I cut the curds into pieces, warm them a little, scoop them out, add a bit of salt, and voila! A quart and a half of low-fat cottage cheese! I feel very clever, though it was the bacillus and the cow and the housemate who milked the cow who did the real work.

One more transformation could turn the whey into ricotta. But we make that with the whey from the other cheesemaking, so our refrigerator is well stocked. (Lasagna, blintzes, cheesecake!) I take the whey out to the chickens, who slurp it up contentedly. It's full of nutrients that flow into the eggs. The composted chicken and cow manure go to the garden to flow into the vegetables.

Simple miracles. Satisfying work, like baking bread or building a shelf. Fresh, delicious food. Nutrient cycles closed right at hand. Health for land and people. Sometimes I wonder, with all our supposed progress, what we're rushing toward and what we're leaving behind.

Please send your cheese making news & photos to: moosletter@cheesemaking.com