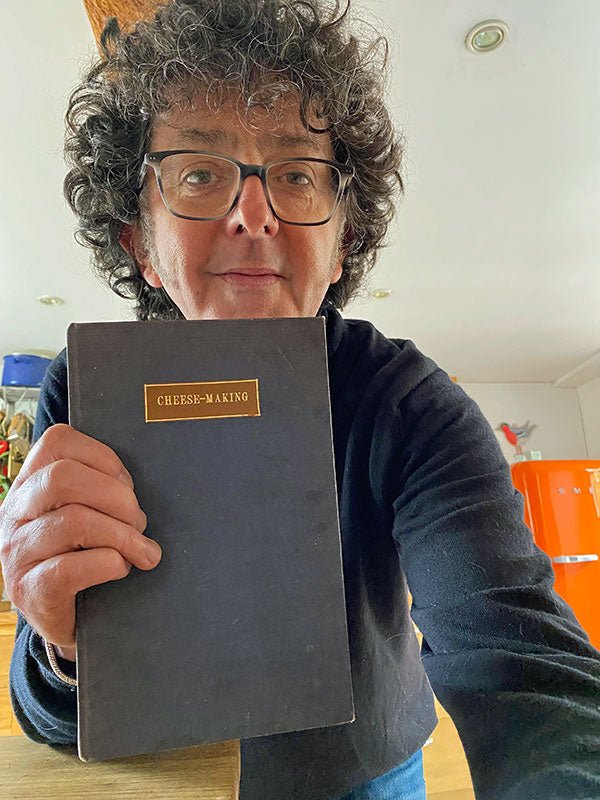

After a career in architecture and design, Nick is enjoying an early retirement, primarily because it affords him time to make a wide variety of fabulous cheeses.

Nick’s Story

My wife and I live in a little village called Tingewick, which is near Buckingham, Buckinghamshire – about 65 miles northeast of London and 20 miles east of Oxford.

We moved to our very old house in 2005 and, whilst Martha (now 25) and Felix (30 later this year) have moved away as kids are supposed to, we are left to stop bits falling off the cottage and to make sure it’s there, dry and warm, when they want to come home occasionally!

The house is shared by two dogs, three chickens and a cat and, depending on the day of the week, that is not necessarily the pecking order!

We have travelled quite a lot over the years and enjoyed trips to India and Japan in recent years. Sara is a textile teacher at a local girls school so we have visited Jaipur to experience hand blocking textile studios around the city and spent a week working in an indigo studio on the outskirts of Kyoto.

Once the world has healed again after the pandemic, we look forward to travelling again and learning more about this amazing world.

How I got started making cheese:

I grew up going to markets with the family, (in the 1970’s) just to do the weekly shopping. My mother went on Tuesdays while we were at school and my dad was at work and we would all go on Saturdays – along with everybody else in the area it seemed!

The cheese stall (invariably there would only be one cheese stall in those days) seemed exotic amongst the butchers, fabric, fish, ironmongery and fruit and vegetable stalls.

There would be big blocks of cheddar and Red Cheshire, flat wheels of brie, exotic cheese with holes in from Switzerland and, as I was growing up in that part of the world, my favourite, Wensleydale straight from the dairy!

Growing up, I loved cheese – from basic student grilled cheese on toast (shushed/spruced up depending who you wanted to impress that week) to comforting homely dishes to satisfy the family on cold winter evenings! I always looked for interesting cheeses on my travels, whether that was here at home in the UK or travel overseas.

I had always joked with friends, too, that if I wasn’t able to do my day job, I would open a cheese shop! So a couple of years ago, I went on a day’s cheesemaking course at the beautiful town of Bakewell in the Peak District in Derbyshire, England, a couple of hundred miles from my front door.

The course was organized by Julie at Hartington’s of Bakewell and run by Phil Heler. Phil works for the family business – Joseph Heler, the biggest craft cheese producer in the UK and one of the last commercial producers of Cheshire cheese.

My first cheese, a Camembert, at the cheese course run by Phil Heler at Hartingtons of Bakewell. I made a lot of notes that day.

I was hooked and have been making cheese ever since. Friends and family continue to encourage me so perhaps some of these cheeses turn out ok.

The wok burner on the gas hop is an excellent position for the domed aluminum pan that forms a water jacket. It makes the temperature easy to regulate. (Do you like the homemade wall tiles?! A local potter was retiring and closing down her business. She was wonderfully eccentric and allowed us to ‘play’ with some tile blanks and her remaining glazes. There were just enough, no room for unplanned cuts and accidents!)

I am lucky that 2 miles away from my front door is a farm that has a Jersey herd. The family sells raw Jersey milk (as well as pasteurized and semi-skimmed milk, double cream (I think you guys call that heavy cream) and delicious ice cream flavours made from the Jersey milk). The farm, BarnOwl Jerseys has been very supportive and it is a fabulous resource. Their milk is a great product to work with.

Fabulous unpasteurized full fat raw milk from the local Barnowl Jerseys herd. I know the farm is exploring non-plastic container solutions.

I mainly make batches based on 8L (2 gal) of milk, but recently have bought equipment to allow me to work with up to 24L (6.3 gal). Whatever recipe you use it seems, whatever quantity you work with, the majority of cheese takes a day to get into the mold or to stand up all by itself.

Since the Covid pandemic hit with a vengeance at the beginning of last year, I have had more time at home and the production and variety of my cheeses has increased as a result.

Even though I have had my fair share of failures (its just part of learning, right? and boy am I still learning), I might yet fill that cheese shop!

Nick’s Cheese:

I started with some basic feta recipes which worked really well with the raw Jersey milk and quickly moved on to cheddar!

I used the New England Cheesemaking cheddar recipe as my guide and made cheddar over and over and over again, trying to be consistent with everything I did, perhaps varying the starter from time to time once I had gotten the method cracked.

The trick for me was to try and keep the cheese for as long as I possibly could and not start eating it after three months when it was just ready! I have now gotten to the stage where I have waxed cheeses that are over a year old and I am tempted to try them but will hold out for as long as I possibly can!

Selection of cheddars, colour coded, in the cheese fridge. I’m looking forward to the beer washed cheddar bottom left, ready at the end of May.

I thought that if I made cheddar for 10,000 hours, I might have mastered it. I think I now know that this isn’t the case. There are so many variables that I am now excited about each cheese and how it might turn out, no matter how ‘consistent’ I think I might have been.

I moved on to Wensleydale after the cheddar. I have always loved Wensleydale (might have mentioned that!) and had tasted some fabulous examples using raw milk and made on the farm, that were supplied by Andy Swinscoe at the Courtyard Dairy.

He had encouraged local farms to make an old recipe from a booklet issued by the Government back in 1930s. Each cheese was so different though the recipe was the same in each case – as clear a case of ’terroir’ making a difference as you will come across.

Contents page. I think it’s amazing to see the French cheese recipes appearing in this book. It was years before these cheeses would routinely appear on the shelves of shops and then supermarkets in the UK.

So, again using the New England Wensleydale recipe, I tackled this cheese. Once I had made it a couple of times and understood the methodology, I tried to make it again using the 1930’s Government booklet – delicious results from both recipes!

Wensleydale made using the recipe from the 1930’s Ministry of Agriculture and Fisheries Bulletin no.43. Mine is waxed as I don’t have an old stone barn to mature it in (yet!)

I have tried out Stilton, thought I should have a go, but results haven’t been good yet!

Camembert works really well with the Jersey milk and I am making this now on a regular basis – very popular with friends and family. They don’t know it yet but the local vineyard will soon be receiving one as a gift as I think it would pair very nicely with their light wines. Perhaps I can sell a few to them over the summer!

Red Cheshire, Lancashire, more Cheddar (all waxed), some Caerphilly (the rind is starting to develop nicely) and some basic Tomme cheeses that I will rub with a smoked paprika and olive oil mix are what I am having a go at just now.

A couple of basic Tomme style cheeses drying off next to some recently maturing Caerphilly. The Tomme cheeses are now washed in a rape seed oil and smoked paprika mix and are housed elsewhere in the fridge.

I am finding the New England Cheesemaking website (cheesemaking.com) extremely helpful in my development as a cheesemaker. Advice from suppliers and manufacturers of equipment and starters here in the UK has also been invaluable. Gianaclis Caldwell’s Mastering Artisan Cheesemaking (now well thumbed) is never far away from me during production either!