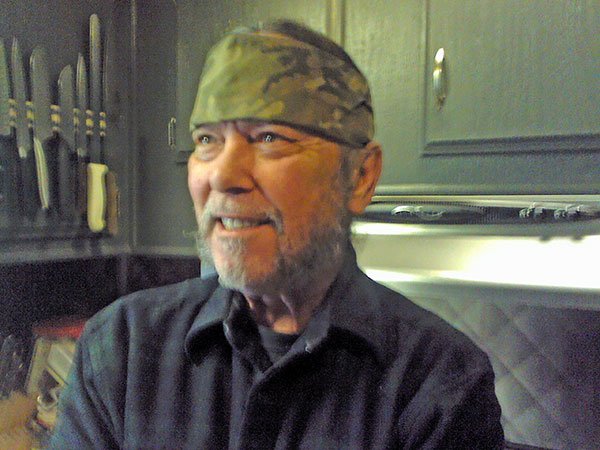

Paul Stovall (67) of Sonora, California is the Frank Sinatra of the cheese making world- doing it his whey! What do we mean? Well, he makes his own cultures and his own molds and his own mats and his own-everything. He’s on a budget, yes, but he’s mainly an extreme “do-it-yourselfer” who doesn’t mind experimenting, even when that means “failing” a good part of the time.

He started making cheese after he had purchased his one millionth overpriced carton of cottage cheese with pineapple. He began making it himself and never looked back. Now he makes his own brie, gorgonzola, blue cheese, Monte d’Or, feta, yogurt, kefir and butterkase.

This is an amazing accomplishment considering that Paul lost one of his legs in a motorcycle accident in 2008. Before that happened, he was a paramedic and a fireman. He also taught CPR in Stockton, the city where he worked. He has 2 sons and a daughter and 8 grandchildren.

Paul’s son, Jordan and grand-baby, Landon

Paul can only handle 1 1/2 gallons of milk at a time and standing at the stove for long periods of time can be difficult. In spite of that, he manages to be very funny, a trait he claims comes from being a long-haired half-breed Indian. We had to laugh out loud when we read this:

“I’ve noted that one huge problem is all this stress on ‘cleanliness’ (mostly banked on use of modern technology and equipment). We’ve sort of lost our way I think. If you watch videos on the old Italian, Swiss and French cheese meisters (whose product is in highest demand), they virtually get naked and swim in the curd by comparison. But then again, they’re using old wooden tables, molds, buckets and open copper kettles, etc. which hold the cultures from one batch to another that overcome unwanted organisms.

Paul makes his own cultures and we don’t endorse that (disclaimer), but he’s well aware of the risks he’s taking and, of course, he isn’t selling his cheese to anybody. He’s having fun and he’s eating large. So, let’s all agree that this article is about Paul and his methods – it’s not one of our “how-to’s”!!!

Paul’s Whey

Calcium chloride:

During my initial struggles to assemble what I thought I was looking for, I came upon calcium chloride (food grade) in the form of ‘Ball’ brand ‘Pickle Crisp.’ 1/2 tsp dissolved in 1/4 cup bottled water and off ya go with that nasty pasteurized milk … Sorry, but that 6.5 oz bottle cost as much a small bottle of pre-mixed solution, not counting shipping and handling and gave me enough compound for months to come.

Paul’s “Pickle Crisp” is in the container with the green top

Molds:

Took out my handy dandy propane torch, grabbed an old 3/16 phillips screw driver I decided was worth sacrificing (heat de-tempers the metal), heated it up and started melting holes. About 500 holes later and coming down from a hydrocarbon fume overdose…. and voila!! Ya got your brand new, home made Ron Popeil pocket cheese mold. You need to find old Tupperware containers that are straight sided (square or round) as tapered ones tend to get a bit rough on tender new cheeses while flipping them. Don’t wanna break our new cheese after all that work.

Paul found these Tupperware containers at WalMart

Set up for draining into the sink

Mats:

I use ‘egg crate’ fluorescent lamp lenses as cheese mats. They have a good 1/2 in. crosshatch construction, ridged, easy to cut to size, keep my cheeses high, dry and breathing etc.. Bamboo mats (which I wove from skewers) are too much of a pain to clean for me and a general nuisance. It may not be the highest grade plastic but works really well on the bottom of my cheese boxes (which I purchase at Staples) for aeration and support. Plus, it’s not too expensive (about $15 for a 2 x 4 ft. sheet), easy to cut, offers excellent support and it’s easy to clean and sanitize.

P. rogueforti:

I’m sorry, but at upwards to $60 for 1/4 oz. of P. roqueforti, I have little choice but to grow my own on cut up pieces of rye bread.

I’ll go out and find a good brie and/or blue cheese. Using clean utensils I’ll extract about 1 tsp of cheese material from the center of the cheese mass and place that into 1/4 cup distilled water in a small blender. With the brie, I try to take an untouched piece of mould mat as well.

The blender has been pre-washed in soap and water and treated with 5% white vinegar. Once blended, I introduce the culture into the milk mass through a clean, fine meshed, stainless steal strainer to avoid lumps.

I use a small clean spray bottle for the same culture liquids, just in case I feel the need to re-inoculate the outer surface of the cheese after forming. I keep these in my small cooler (38-42 F) long term aging fridge for upwards to a couple weeks before changing them out. I also have a couple pieces of rye bread being happily consumed by P. roqueforti which when done I will dry, grind and use to culture. Other prime sources for cultures are honey comb with larvae, ant mound earth, etc.

Paul’s 2 caves

Other cultures:

I don’t really ‘make’ the cultures so much as harvest them. They’re pretty much self propagating if treated properly. I use ‘cultured buttermilk’ (1/2 pint for about 90 cents) for my mesophilic and plain activated probiotic yogurt for my thermophilic. I have plans on isolating both of those out of real kefiran later on but these work for now. (Kefiran is the sticky thread-like gel that forms between kefir grains.)

I realize that there is a chance for contamination by extracting from store bought cheeses and one must exercise caution. But then again, many of the cultures that folks buy are exposed to harsh conditions during shipment – not conducive to culture viability. Using my method, I’m in control of conditions from the time of purchase, through transport, storage, sample collection and handling from a known viable living source. Knowing basic bio lab procedure techniques helps, too, and I have yet to have a problem.

That and cheese, though finicky, is really rather forgiving and tolerant too. Like any living thing, if one introduces enough of the desired culture strain and it’s properly nurtured, it will take over and overwhelm unwanted species. From then on, it’s a matter of timing, knowing when and for how long to produce the desired result.

Like with evolution. Both positive and negative variations can and will be made. The positive oft times result in the discovery of a new or improved cheese. A couple of degrees this way or that. A few minutes more or less…. may produce a delectable result. Thankfully our senses also warn us of bad results. Imagine the surprise of the first Benedictine Monk who was brave (or hungry enough) to not throw that stinking, nasty, ugly wheel away. He just knew he had made a horrible mistake. The smell alone reeked of death but instead, he bit into what would become Limburger.

Interior of the larger cave

Paul’s Cheese

Mushroom Infused Brie:

I put up 5 small half goat’s/cow’s milk, mushroom infused, ‘ashed’ (white oak charcoal) triple-creme brie cheeses about two weeks back. What I did was to take dried shrooms (in this case ‘Lions’ Mane’) and sprinkled them (along with a bit of ash) between layers of curd while molding. I dry salted instead of brining because they were so tender.

They’re starting to bloom with P. candidum but appear to be developing a bit of B. linens (kinda orange-ish color). They still smell okay so far. Was thinking that they would be excellent with my Italian AlFredo Sweet Breads recipe (now THAT’S good eats).

Paul’s mushroom-infused brie – in the cave for 3 days. (Paul uses his grates to keep the cheeses up and out of their own sweat but he puts a couple folds of paper towel under that and wets them. He adjusts the humidity by either locking the plastic ripening box lids down or setting them askew as needed.)

Later: The bries I was concerned about pulled through, thank you. They’re all a’fluff with a thick layer of P. candidum and looking and smelling well. Geez. These things are more like baby sittin’ little kids for cryin’ out loud. First ya gotta make them, then take ’em out on a regular basis and pat ’em on the po po, burp ’em, make sure they’re all comfy, worry over them til they’re all grown up…. Sometimes they grow up good, sometimes not so good. THEN EAT ‘EM anyway.

Three weeks later

Blue

My first ever attempt at any sort of cheese (outside of cottage cheese) which I hope won’t kill me – blue. The poor thing. It’s three months old now but I’m sorta afraid to ‘cut the cheese’ as I’m afraid of what may come out forthwith. It’ll probably turn out to be some sort of weird mutant limburger from the planet ‘Oh, My God!’ or something. That or the monster green cheese from Luna that ate Lodi Ca.. If they call the EPA on me, I’m outta here.

Paul’s blue

Gorgonzola

It should be ready in June

Mont d’Or

I have my spruce strips soaked and I started my Mont d’Or this afternoon (ripening as I write). It’s going to be really interesting to work with real rennet for the first time. (Paul was trying to use Junket until very recently.) I used about 1/4 cup non-chlorinated water with 3-4 drops per gallon of milk as per instructions. The Junket was giving me a ‘grainy’ set at best and that at usually 1/2-1 hour or so extra time to set. ‘Course that gives ripening too much time. But I pretty much slop cultures in anyway. Mesophilic is cultured buttermilk I allow to set out for some time to ‘thicken’ and thermophilic is probiotic yogurt.

Those are spruce cambium strips wrapped around the Mont d’Ors

Butterkase

Paul used Jim Wallace’s recipe from our website (click here):

That was a VERY interesting cheese to make and I was blown away with the aroma alone. It still reminds me more of a really rich eggnog’ishy aroma (at least to date). I didn’t have any geotrichum prepared so doped it with a bit of P. candidum instead, using ’bout a 1/4 cup each cultured buttermilk (left over from a cultured butter I’d made) and active yogurt as primary cultures.

This is my jury rigged double boiler. The two pots are just about the same diameter so I took my ‘wok’ ring and turned it upside down. It fits into the lower pot perfectly and keeps the milk pot from sliding down and rockin’ around and making a mess. You may note that I’ve got a magnetic digital thermometer stuck to the fume hood with a flexible cord probe that hangs in the milk. That one’s more to monitor and I’ll set to below my target temp to notify my when I’m getting close. I use a more precise hand held digital thermometer to monitor the actual temperature.

It had all already come up to temp. and I’d added my calcium chloride and pre-prepared cultures and was letting the milk ripen at this point. The mesophilic culture was a combination of half/half store-bought cultured buttermilk and buttermilk I had salvaged from my ‘cultured’ butter to equal about 1/4 cup. The thermophilic was made with a couple Tbs. probiotic plain yogurt and milk to equal 1/4 cup. Both had been mixed and allowed to sit out overnight to ‘awaken’ before use. I allowed the milk to ripen for the proper time then placed the pot back on the double boiler to bring the whole thing up to 106F to kill off the meso culture and get the thermo culture really goin’ to do its’ part.

That’s my cheese cloth. It’s a bit messy to pre-sterilize EVERYTHING in the pot prior to starting. I usually reserve that for just the pot and hard utensils like my slotted spoon and curd knife. I cut the appropriate size cloth, wet it, place it on a clean plate and microwave it for about 30 seconds or so until it’s good and steaming. Sterile.

If I’m going to need a colander for curd draining, I usually use good old handy-dandy cotton tea towels. You can get 4-5 of them for a couple bucks. They’re tough and reusable. Same thing there. Just get them soaking wet and nuke ’em til they’re nice and steamy. Ya may wanna unfold them a bit before the nuking, then just leave ’em be til needed. That and they get pretty hot too, so they do need to cool a bit before handling. Much easier than trying to sterilize them in a pot then dip ’em out, etc..

These are my curds healing first off and then after a couple stirs. Yes, I cut the cheese. I followed procedure here with the curds til I got the right texture to maintain an open mat yet retain good moisture.

This is my hot screw driver perforated, handy-dandy, 5 in x 5 in, Ron Popeil, pocket cheese mold I’d made from an old straight sided Tupperware. The CD disk there fits just right down on the top of the cheese. I used a mayonnaise jar full of ‘treacle’ syrup I’d made for the weight (about 3 lbs.) to consolidate the curd. I had introduced the cheese cloth as best it would go, then rubber banded it around the edge and trimmed it to keep things from goin’ nuts, then just ladled in the curds.

I did use the ‘washed curd’ method on both of my butterkase. I wanted to make the ‘sweet’ er version so spilled off about 1/2 the whey and replaced it with 104F water and allowed it to sit for the required time while doing the gentle occasional stir.

This is a styrofoam cooler I had used to cultivate my sake moulds a couple years ago. It worked perfectly for keeping my cheese warm for the required 4-5 hrs during acidification and curd consolidation. I filled a 1/2 gal. plastic milk jug full of warm tap water and nuked it til it was hot . Placed that inside the cooler along with the cheese to keep things warm. I only had to re-heat the water jug once in all that time. As you can see, I had inserted my good digital thermometer in the cooler lid to keep a watch on the temperature as it wasn’t supposed to drop much below 98F during incubation period.

After a good 10 or so hours, the cheese was lookin’ good and I was finally able to put things to bed after the cheese’s last ‘flip.’

Here he is at just over two weeks and starting to change color. I had to take him out for a wash, burped him, patted him on his little popo, told him I loved him and tucked him back into bed.