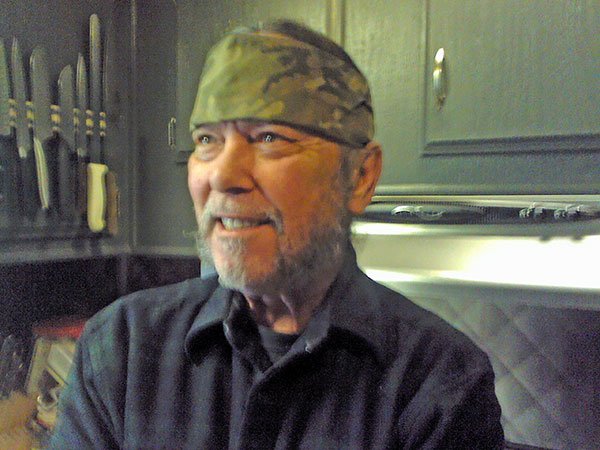

Claude and Lynda standing in front of the cave he built from a closet.

What a Team!

Claude buys the equipment, sets it up and builds whatever Lynda needs to make her fabulous cheese. (Lucky lady!) Meanwhile, according to Claude, Lynda is an absolute cheese making kook. (We think she’s an absolute MASTER home cheese maker!)

Claude and Lynda have been married for 38 years, have 4 grown kids and 5 grandkids. Lynda enjoys gardening when she isn’t making cheese. Claude has been retired for just over 10 years.

Claude and Lynda have been married for 38 years, have 4 grown kids and 5 grandkids. Lynda enjoys gardening when she isn’t making cheese. Claude has been retired for just over 10 years.

His hobbies include sausage making, smoking fish and meats, as well as hunting, shooting and fishing. He is also a story-teller and he has had his own TV show on local television for 3 years.

Claude explained, “It’s a show, in French, about story-telling. I tell a short story at the beginning of each show, then I have a guest that tells a longer story, followed by an interview. This year, after 3 seasons, we’ll be starting a new concept which focuses on the whole French-Canadian culture and traditions. One of the topics? You guessed it – artisan cheese making the way our ancestors did it.”

When Lynda started making cheese 4 years ago, Claude’s made her a cave out of a closet. He installed a room air conditioner with a Cool-bot for the summer. For the winter, he put in a bathroom ceiling fan which draws heated air from the basement and blows it into the cheese “cellar.” It is thermostatically controlled. He recently solved the very common humidity problem with the use of 2 humidifiers (shown here).

The shelving is white pine, 1″ thick, and the glass doors are just plain French doors. The lighting is set to shut off automatically after 10 minutes, so if they forget to turn it off, no harm is done.

Meanwhile, Lynda has become a fabulous cheese maker. She is strictly an amateur because she can’t get a license for her home-based dairy and she uses milk from Costco because she can’t buy farm-fresh milk in Ottawa. But, her family and friends are “eating large!”

In case you missed it, a year ago, in the Moos-Letter, we posted a wedding cake Lynda made for her daughter:

The bottom layer was cheddar and chives, 2nd layer was gouda, third layer was Colby and the top was a Brin d’Amour – approximately 40 lbs of cheese!

Claude’s Story:

We are pleased to share with you my wife Lynda’s cheese “factory.” She started making cheese 3 years ago. While watching TV, they showed a commercial for some monks in Oka, Quebec, who used to make the world-renowned Oka cheese. She told me that she would love to be able to make cheese.

We are pleased to share with you my wife Lynda’s cheese “factory.” She started making cheese 3 years ago. While watching TV, they showed a commercial for some monks in Oka, Quebec, who used to make the world-renowned Oka cheese. She told me that she would love to be able to make cheese.

Well, given that I had my computer on my lap, I Googled home cheese making and found the web site www.cheesemaking.com. I ordered the Mozzarella and Ricotta kit. She loved it. Then, I ordered a hard cheese kit.

We were lucky, as we had several 5-gallon stainless pots. But, as her mania grew, she outgrew the 5-gallon pots, so we moved up to 9-gallon pots. More than enough, right? Well, not quite.

So then, we bought a 20-gallon pot, and we had done a lot of work in the laundry room so she could use it to make cheese. Well, as you probably guessed, she outgrew the room and the 20-gallon pot.

The next thing I know, I am relocating the laundry room into the furnace room (which was also my gun room). The laundry room would become her cheese making kingdom. We ordered the 55-gal.+ vat from Pro-Com Inox in Quebec (the vat was a fantastic bargain – with all fittings, etc., it cost us $1700 CDN ($1345 with the present exchange rate).

Given that we had moved our gas dryer out of the room, we had a spare gas connection, so in went a cooktop. Now, you see the room in its final iteration. Any bigger, we will have to buy or rent a cheesery.

I thoroughly enjoyed setting everything up for her, as I have always enjoyed inventing and adapting, so she has been keeping my inventiveness thoroughly challenged in both the cheese room and aging room.

The white cabinet has a quartz top, as quartz is non-porous. The metal cabinet is stainless.

Another view of the cheese room. In the lower right corner, you can see Lynda’s cheese vat with its HDPE cover (high density polyethylene).

In this picture, you can see Lynda’s cheese vat, which holds about 55 gallons of milk. Beside it is a natural gas cooktop used to heat the water for the vat and the milk for smaller batches. The water

for the vat is heated in a 6-gallon pot and circulated using a wet saw pump.

The hydraulic jack is used on her cheese press. All of the hydraulic oil was drained, the jack was thoroughly cleaned and the oil replaced with canola oil. Not seen in the picture is a large coil spring

which is placed atop the jack to maintain fairly constant pressure as the cheese drains.

Pressure on the cheese is monitored using a scale on which the cheese moulds sit.

We also have 2 other presses that use weightlifting weights for pressing the cheese.

The floor of the room is all ceramic, and we installed rubber baseboard along the walls, and sealed the bottom with silicone, which allows her to not have to worry about water or whey on the floor.

The vat was custom-made by a company in Quebec, at an extremely reasonable cost, and is 100% stainless, including all the fittings.

Update:

Since he finished the make room, Claude has begun another project- making cheese boxes. If you are interested in having him make one for you, contact him at claudegarneau@gmail.com