A while back, one of our readers asked us to connect her with Sandra Daniels, a missionary in Kenya (article in 2011). This reader was planning to teach cheese making in the slums of Nairobi to South Sudanese refugees. Specifically, she was hoping to teach the people to make Indian paneer and Middle Eastern mudaffara (braided cheese which is based on mozzarella). She would be bringing our rennet tablets with her, but she was hoping she would eventually find a local source for rennet in Kenya or Sudan.

We asked her to keep in touch, and after she did, in fact, go to Nairobi, she sent us this report.

Molding Mozzarella in the Slums of Nairobi, Kenya

By: Anonymous

For seven years, a church outside of New York City has given practical and financial support to a South Sudanese refugee church in Nairobi, Kenya. Once a year, the church sends a team to Nairobi to look in on the African church and to teach. Many of the classes have the purpose of increasing the stock of practical skills to allow the church members and their friends to complement their income. This year’s main skill taught was basic milk processing and was intended to take the church members back a little bit to their pastoral roots.

The church building.

The wee corrugated iron church is home to over 500 people. They are members of many different South Sudanese, Sudanese, and Kenyan tribes. The main constituent are people of the South Sudanese Dinka tribe. They – among others – are pastoralists. The cows of the Dinkas have the most impressive horns.

South Sudanese cows – None of these live in Nairobi. (Picture courtesy of https://commons.wikimedia.org)

Unfortunately, the wars that have been raging in South Sudan for many decades, have displaced thousands of people, away from their herds and pastures, their cattle usually taken in hostile raids. Now that they have come to live in the slums of the city of Nairobi, keeping cows is practically impossible. You will encounter scraggly sheep and goats in the slums that feed on scraps of human food and the odd tussock of grass. You will also encounter small cow herds being driven through the slums from one small grassy patch to the other by the local Kenyan Maasai people. But the danger of theft, lack of stable accommodation and no access to feeding grounds, make it impossible for the South Sudanese refugees to keep cattle. This means that herding and milk processing skills are neither practiced nor passed on.

Goats seen in the slums.

Fortunately, both pasteurized and raw milk are available in the slums at around 60 US cents per liter (quart) for small quantities. The team brought yogurt culture, rennet, citric acid, cheese cloth, and thermometers with them from the USA. From previous visits, the team knew that the other tools could be found in Nairobi itself. Consequently, there was nothing standing in the way of the 2018 Africa Team to teach very basic milk processing skills.

A few of the cheese making materials obtained from New England Cheesemaking Supply Co.

When the team arrived in Kenya, they found that the department/grocery store Nakumatt, their main supplier of tools, had gone bankrupt. Pity, they had sold the best cooking implements in town. Their successor, French Carrefour, was in the process of redecorating the vast store area, and therefore, was only running at 20% capacity.

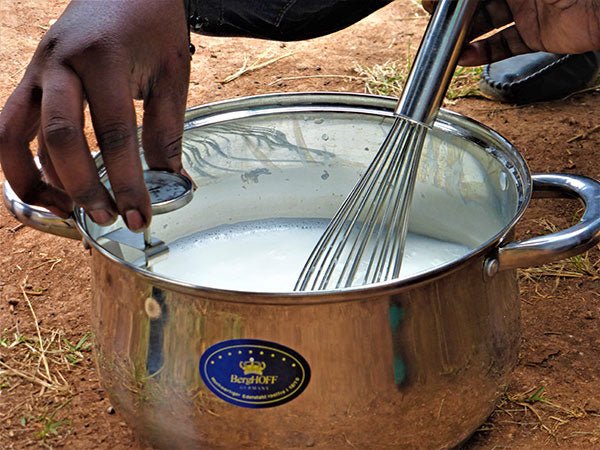

It meant that the team had a chance to go shopping in the slum market. It covers a vast area and houses a gazillion simple huts, stalls, buildings – all selling goods from all over the world, including famous brand names, and of course, local produce. It took several attempts to find stainless steel pots, spatulas, egg whisks, and jars with lids. Items that are readily available in US stores are not always easily found throughout Nairobi.

Shopping in the slums.

Back at the church, all is very simple: no fridges, no microwaves, no gas or electric stoves. Since the church’s coal stoves were old and broken, the team invested in two high-efficiency coal stoves (only US $56/ea). It meant that they could produce more heat at lower cost.

The high efficiency coal stoves.

The team first ran a demo class that was open to the whole church community. All received detailed visual and written instructions about sanitization, flash pasteurization, yoghurt making, paneer making, mozzarella and Sudanese mudaffara cheese making. After the two general demo sessions, the team took thirteen women through practical training sessions in the hope that the knowledge and the processes would stick so that they could go into production and teach others. Meet the 2018 cheese making class:

Yoghurt is expensive in Kenya: 1.5 dl tubs (5 fl. ounces) of regular yoghurt cost more than US $1. That is a lot of money for people who at the most earn around US $100/month on average (many earn less). The team, therefore, taught the members of the church how to make their own yoghurt. For the large class, they used a tub of local yoghurt to culture ten liters (2.6 US gallons) of yoghurt. The US yoghurt cultures unexpectedly ended up with a fine Catholic nun who runs a station in West Kenya near Victoria Lake. She herself is the daughter of a North Italian cheese maker. She will use the cultures, citric acid, and all the recipes the team gave her to train the African women in her charge.

The “yoghurt babies” all wrapped in clean terry cloths and kept warm for 24 hrs in a cardboard box.

The team chose to teach how to make Indian Paneer cheese since the process is easy and the materials are readily available. In addition, there is a large Indian constituent in Nairobi. A block of 250 grams (9 ounces) of Paneer cheese can easily fetch $3.75 – $5.00 in the local market, plus it can be sold in the streets as part of cooked dishes.

Pressing Paneer loaves.

Mozzarella and mudaffara cheese making is the secret of a particular group of people in Sudan. When South Sudan split off from Sudan, that knowledge primarily stayed in Sudan. The team flash-pasteurized the milk as a first step, as the mozzarella process does not bring the milk up to the boiling point. The first lot of milk produced good and strong curds but needed longer to set than the US milk. The elasticity of the curds was heavenly.

Pulling and molding the mozzarella.

Once the mozzarella balls had been shaped, the team took them one step further and transformed them into braided string cheese (mudaffara = braided in Arabic).

Transforming the mozzarella into string cheese.

Mudaffara cheese is likely to have entered Sudan from the Middle East. Usually, kalonji seeds are added to the mudaffara cheese. Upon the request of the church members, we left the seeds out.

Et voilà – After a total of 5 hours …

The finished mudaffara braids.

Unfortunately, the team learned that the quality of the milk varied over the different days. A lesson was learned for next time!

See you next year… making Feta?

The 2018 Africa Team would like to express their most cordial thanks and appreciation for the kind and generous support given them by New England Cheesemaking Supply Company!