|

| Suzanne does not really have a huge, monster hand- it just appears that whey! |

Everybody loves cheddar!

Suzanne not only makes fabulous cheese- she takes mouthwatering pictures of it. This month she has outdone herself both ways as you will see in her article below.

Note: Don’t forget to try for her giveaway. Details are at the end of this article and at her website- Chickens in the Road. Giveaway closed.

Stirred-Curd Cheddar

By Suzanne McMinn

http://chickensintheroad.com/cooking/stirred-curd-cheddar/

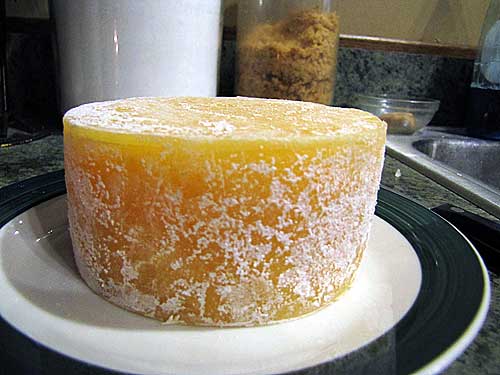

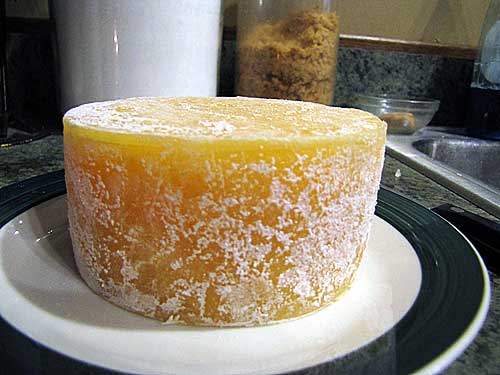

My Cheddar!

Cheddar is one of the most popular cheeses in the world, with a long history going back to the cheddar caves in England, where it was known as the cheese of kings. Cheddar can be made anywhere, though–it is a process, not a place, and the traditional process involves cheddaring, in which the drained curds are allowed to coagulate into one mass and are then cut into slices, stacked, turned several times, then broken up into smaller pieces (milled). This is a little extra effort, and many store-bought cheddars today aren’t made this way. They are made by a short-cut process often known as stirred-curd cheddar, which is also a perfect alternative for the new cheesemaker wanting to try their hand at cheddar with a little less fuss.

In stirred-curd cheddar, the curds are prevented from matting together by stirring and you skip all the slicing and stacking and milling. (Stirred-curd cheddar is a close relative to colby cheese, in which the curds are washed as part of the process.)

The natural color of cheddar cheese is a creamy off-white, but it is traditionally colored with annatto, a vegetable dye, which lends the rich orange we expect from certain cheeses. It has no effect on the taste of the cheese, so you can leave it out if you prefer, but it’s kind of fun to use, especially the first time you see your cheese suddenly look like cheese from the store. (Look, it’s orange!) Like you did a trick. And you did! You made cheese!

I made quite a bit of traditional cheddar last summer, with mixed results. Now that I’m tackling my cheese challenge for New England Cheesemaking one cheese at a time, I decided to re-tackle cheddar, starting with the easier version first. Why didn’t I think of that before? (I do do things the hard way!)

Milk, milk, milk. The best milk to use to make cheese is farm-fresh! But you don’t have to have a cow to make cheese.

If using store-bought pasteurized milk, for a two gallon recipe, you may want/need to add 1/4 teaspoon calcium chloride diluted in 1/4 cup cool water while heating the milk in Step 1. This will help the curds to set properly. See more about milk for cheesemaking here.

My cow, Beulah Petunia. She loves me. Sorta.

Glory Bee, my up-and-coming milker. I’ve been trying to get her to take a marshmallow from me for weeks.

I think she thinks I’m trying to poison her. She’s very suspicious.

Clover: “I’ll work for marshmallows!”

You can use goat milk in the stirred-curd cheddar recipe in this post!

Donkey milk stirred-curd cheddar?

My beloved Poky.

She’ll take a marshmallow any time.

Did you know that donkey milk is good for you? People with allergies to cow milk can drink donkey milk, and it’s growing in popularity in some European countries.

Poky might be pregnant! She’ll be in milk!

But–

I don’t think so on the donkey milk. I don’t have any cow milk allergies anyway. Whew. Would you drink donkey milk? I have to know.

The following recipe is from Ricki Carroll’s Home Cheese Making. You can use the same directions for either cow or goat milk. (I don’t know about the donkey milk.)

How to Make Stirred-Curd Cheddar:

2 gallons whole milk (cow or goat milk)

1 packet direct-set mesophilic starter

2 drops cheese coloring per gallon, diluted in 1/4 cup water (optional)

1/2 teaspoon liquid rennet (or 1/2 rennet tablet) diluted in 1/4 cup cool, unchlorinated water

2 tablespoons cheese salt

Step 1. Heat the milk to 90-F. Add the starter and stir well. Cover and allow the milk to ripen for 45 minutes.

Step 2. For cheese coloring, use 2 drops per gallon of milk–4 drops total–diluted in 1/4 cup of cool water.

Add the coloring to the milk and stir well to distribute evenly.

Cheese coloring must be added before the rennet, and stirred in well as it can destroy the coagulating ability of the rennet. If you find later that you forgot to add the coloring, forget it. You can’t add it later. Make white cheddar.

Also, be careful with how much coloring you add! Don’t get carried away. When you put the coloring in, it will look like it didn’t even make a difference. There’s still a lot of water in the milk. You’ll really only see the result of the coloring after the cheese is pressed. The color comes out more and deepens as the cheese air dries in the first few days following pressing. Follow recipe guidelines for adding cheese coloring. If you make cheese while you’re drinking and forget you put the coloring in then add more, you’ll end up with clown cheese! Don’t make cheese while you’re drinking!!

When diluting the rennet, don’t use the same container you used to dilute the coloring.

Step 3. Make sure the milk’s temperature is 90F. Add the diluted rennet and stir gently with an up-and-down motion for 1 minute. If using farm-fresh milk, top-stir for several minutes longer. Cover and allow to set at 90F for 45 minutes, or until the curd is firm and gives a clean break.

Step 4. Cut the curd into 1/4-inch cubes. Allow the curds to set for 15 minutes.

Step 5. Heat the curds to 100F, increasing the temperature no more than two degrees every 5 minutes. This should take about 30 minutes. Stir gently to keep the curds from matting.

Step 6. Once the curds reach 100F, maintain the temperature and continue stirring for 30 minutes. Let set for 5 minutes.

Step 7. Drain off the whey. Pour the curds into a large colander and drain for several minutes. Do not drain too long, or the curds will mat. Pour the curds back into the pot and stir them briskly with your fingers, separating any curd particles that have matted.

Step 8. Add the salt and blend well. Do not squeeze the curds; simply mix the salt into them.

Step 9. Keep the curds at 100F for 1 hour, stirring every 5 minutes to avoid matting. The curds can be kept at 100F by resting the cheese pot in a sink or bowl full of 100F water.

Step 10. Line a 2-pound cheese mold with cheesecloth. Place the curds in the mold. Press the cheese at 15 pounds of pressure for 10 minutes.

I’ve taken to using disposable cheesecloth. It’s so much easier.

Step 11. Remove the cheese from the mold and gently peel away the cheesecloth. Turn over the cheese, re-dress it, and press at 30 pounds of pressure for 10 minutes.

Step 12. Repeat the process but press at 40 pounds of pressure for 2 hours.

Step 13. Repeat the process but press at 50 pounds of pressure for 24 hours.

Step 14. Remove the cheese from the mold and peel away the cheesecloth. Air-dry at room temperature for 2-5 days, or until the cheese is dry to the touch.

Step 15. Wax the cheese (if desired).

Sometimes I wax, sometimes I don’t.

In some ways, it’s easier to “wax it and forget it” but I do prefer the looks of the unwaxed cheeses. They take some extra tending, though.

Step 16. Age it at 45-55F for 2-6 months.

Yield: 2 pounds.

My experience: Stirred-curd cheddar is much easier to make than traditional cheddar. It’s also a lot faster. It takes about five hours to get traditional cheddar ready to go into the press, but closer to three hours for stirred-curd cheddar. In the past couple of months, I’ve made several stirred-curd cheddars, and have even opened one! It does make a creamy cheddar-like cheese in a short amount of time. From the time/labor perspective, the stirred-curd wins hands-down, so I know I’ll keep making this one, though now that I have a little more experience under my belt, I want to try my hand at traditional cheddar again, too.

The cheeses I don’t wax develop a natural white bloom that brushes right off.

According to cheesemaking expert Jim Wallace of New England Cheesemaking,

“The white mold is absolutely okay and can easily be wiped down with a dry brush or cloth or with a brine-soaked cloth. Cheddar is not normally made with a natural rind because of the dry curds at molding. It is usually waxed or cloth bandaged and the mold problem then disappears.”

Here’s a hunk cut off, going into my handy dandy food processor.

Shredded.

And melted on top of black bean burgers.

I did that! So can you!

Suzanne’s Giveaway

To help you get started making cheese, New England Cheesemaking is providing a package for Suzanne’s giveaway, including (value of each item in parentheses): a hard cheese mold ($15.95), mesophilic culture ($5.95), veal rennet ($6.50), red wax ($5.50), cheese brush ($7.95), cheesecloth ($5.95), cheese salt ($2.95), and calcium chloride ($4.95). The total value of the package is $55.70. Note: This giveaway is open to U.S. residents only. (P.S. Or at least a U.S. shipping address. You can have a friend or relative send it on to you if they have a U.S. shipping address.)